Unusual Dome Awaits Baseball Season in Houston

Louis O. Bass, A.M.

ASCE Vice President, Roof Structures, Inc.,

Webster Groves, Mo.

Civil Engineering - ASCE, January 1965

Covering over 9 acres of land, the

new

domed stadium in Houston, Texas, offers a playing field and seating

area that is completely covered over. The dome has an outside diameter

of 712 ft. with an overall height of 208 ft. Lamella trusses 5 ft. deep

frame the roof, and there is a total of 2,150 tons of steel in the

350,000 sq. ft. of roof frame, plus a 376-ton tension ring. The stadium

will be completely air-conditioned utilizing equipment with 6,000-ton

cooling capacity to circulate 2,000,000 cu. ft. of air every minute.

Radio-controlled thermostats will be used for the playing area when it is

converted for seating for some sports.

Covering over 9 acres of land, the

new

domed stadium in Houston, Texas, offers a playing field and seating

area that is completely covered over. The dome has an outside diameter

of 712 ft. with an overall height of 208 ft. Lamella trusses 5 ft. deep

frame the roof, and there is a total of 2,150 tons of steel in the

350,000 sq. ft. of roof frame, plus a 376-ton tension ring. The stadium

will be completely air-conditioned utilizing equipment with 6,000-ton

cooling capacity to circulate 2,000,000 cu. ft. of air every minute.

Radio-controlled thermostats will be used for the playing area when it is

converted for seating for some sports.

Houston's new domed stadium--the first major-league indoor baseball

park--is nearing completion and will be ready for the first game of the

Houston Colts this spring. The stadium is a domed circular concrete and

steel framed building with an adequate playing field for both baseball

and football. Covering an area of over nine acres, the structure has an

outer diameter of 710 ft with a clear span of 642 ft. The roof rises to

a height of 202 ft above the center of the field. Seating up to 66,000

can be arranged to accommodate any type of sport or meeting from rodeos

to national political conventions. Some 10,428 seats at field level are

contained in two stands which rotate 35 degrees from baseball position to

parallel for football position. Movement is on tracks with power by

motors.

Engineering problems were monumental and included some entirely new

ones. Growing a suitable grass on the playing field inside involved not

only mechanical engineering, horticulture and maintenance, but careful

calculations by physicists to determine how much sunlight should be

allowed through the roof. Stratified heat will occasionally require

heating of the lower areas and cooling of the upper ones.

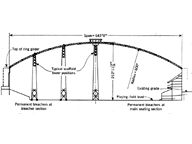

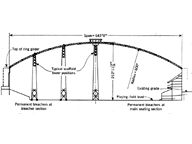

An older problem was how to span a distance of 641 ft. 8 in. without

interior supports. Of course this is a relatively small span for bridge

builders, but unusually large for a roof structure. At no time was

consideration given to a roof that would open and close since this would

play havoc with the air-conditioning system and be much too costly as

well. Cost estimates of various fixed systems were assembled and it was

determined, as a result of this information, that the basic design would

be a steel lamella-type trussed roof structure. This system had

previously been employed successfully on several dome spans up to 285 ft.

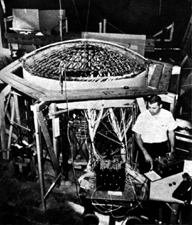

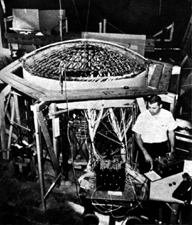

Thirty seven erection towers were

necessary in building Houston's new domed stadium. The tallest tower, at

the center of the structure, was 212 ft. This and the other towers were

salvaged by the erector. The view shows the lamella dome after 19

working days. It is expected that the dome will be completed and ready

for the opening game of the Houston Colts in April.

Thirty seven erection towers were

necessary in building Houston's new domed stadium. The tallest tower, at

the center of the structure, was 212 ft. This and the other towers were

salvaged by the erector. The view shows the lamella dome after 19

working days. It is expected that the dome will be completed and ready

for the opening game of the Houston Colts in April.

The stadium is circular in plan and

has six levels of seating. The playing field is set 25 ft. below

grade. Movable sections of grandstand seats rotate about 35 deg. over the

playing-field level, from baseball position to football position.

The stadium is circular in plan and

has six levels of seating. The playing field is set 25 ft. below

grade. Movable sections of grandstand seats rotate about 35 deg. over the

playing-field level, from baseball position to football position.

Among other types of systems given consideration were: geodesic, in

steel and aluminum; suspension-type cantilever lever trusses; the Kaiser

dome; a timber space frame; an aluminum Geolatic space frame; and even

an air pressure-supported flexible covering.

The architects, Lloyd and Morgan associated with Wilson, Morris, Crane

and Anderson, secured the services of Roof Structures, Inc., in St.

Louis Mo., for the engineering design of the lamella roof. Praeger,

Kavanagh & Waterbury, engineering consultants in New York, were retained

to check all structural engineering, and they in turn engaged Dr. Henri

Marcus, F. ASCE, to check the roof calculations. Further, Roof

Structures, Inc., consulted Dr. Z. S. Makowski of London University for

theory validity in addition to the normal checks by Walter Moore,

structural engineer in Houston--a case of consultants who had

consultants who had consultants!

Model testing Roof Structures, Inc., decided to set up a

research project headed by the author, their vice-president in charge of

engineering, to analyze mathematically the complex framed dome and then

to build a test model to verify the analysis. It was also necessary to

determine the wind forces applicable to the roof surface when a dynamic

wind force of 40 psf is applied by the occasional hurricanes prevalent

in the Houston area. Dr. G. R. Kiewitt of Roof Structures, Inc., decided

that a wind tunnel test should be made. A l/8-in. scale model was tested

by McDonnell Aircraft Company of St. Louis for 48 different conditions

of opening positions and angle of attack by the wind. The data gathered

support a strip method application of the ASCE Subcommittee Report No. 31,

"Wind Forces on Tall Buildings." The building is designed to withstand

hurricane wind gusts of 165 mph with continuous forces of winds of 135

mph. This also causes an uplift of 40 psf, which has been taken into

account.

Model testing Roof Structures, Inc., decided to set up a

research project headed by the author, their vice-president in charge of

engineering, to analyze mathematically the complex framed dome and then

to build a test model to verify the analysis. It was also necessary to

determine the wind forces applicable to the roof surface when a dynamic

wind force of 40 psf is applied by the occasional hurricanes prevalent

in the Houston area. Dr. G. R. Kiewitt of Roof Structures, Inc., decided

that a wind tunnel test should be made. A l/8-in. scale model was tested

by McDonnell Aircraft Company of St. Louis for 48 different conditions

of opening positions and angle of attack by the wind. The data gathered

support a strip method application of the ASCE Subcommittee Report No. 31,

"Wind Forces on Tall Buildings." The building is designed to withstand

hurricane wind gusts of 165 mph with continuous forces of winds of 135

mph. This also causes an uplift of 40 psf, which has been taken into

account.

The preliminary analysis was a shell analogy used to select sizes for

the 5-ft-deep lamella trusses framing the roof. Four cycles of

analyzing-resizing by an elastic analysis were necessary to find the

most economical design. Results required 2,150 tons of steel in the

350.000 sq ft of roof frame, plus a 376-ton tension ring. Some lamella

units were approximately 122 ft long, and ring units 32 ft. Thirty-seven

erection towers were necessary for centering. The tallest tower was 212

ft at the center of the building. All the towers were salvaged by the

erector. Neglecting the weight of the towers, the weight of dome and

ring per square foot was 16.6 lb. The structure was designed for a live

load of 15 psf, a one-sided loading of 7.5 psf, and a dead load of 30 psf.

Loading conditions were rather complex, involving arrangements for

unsymmetrical mechanical equipment, sonic dynamic loading from aircraft,

temperature fluctuations of 140 deg, wind loading varying around the

structure, and of course live load.

An interesting detail of construction is found in the column connection

details. The columns are free to move radially and are semi-rigid

tangentially under the tension ring. The column stubs are pinned at the

lower end 6 ft from the tension ring, and have rockers at the upper end.

This arrangement prevents the build-up of primary and secondary moments

between the roof and the supporting structure.

Skylights The roof contains

nearly 4,600 skylights and the pattern of skylights selected

to accomplish the acoustical needs of the structure left 50 percent of

the roof covering above the field available for the admission of light.

Fixed skylights in the perforations were designed with two layers of

plastic (to control condensation). The outer layer is clear for maximum

transmission of light; the inner layer also has a high degree of

transmission but is diffusive to scatter light to all parts of the

field. Seating is arranged on six levels allowing for six front rows.

It is arranged so that the spectator will enter the stadium at about the

mid-level of seating and proceed either up or down on wide, low-gradient

ramps or escalators.

Skylights The roof contains

nearly 4,600 skylights and the pattern of skylights selected

to accomplish the acoustical needs of the structure left 50 percent of

the roof covering above the field available for the admission of light.

Fixed skylights in the perforations were designed with two layers of

plastic (to control condensation). The outer layer is clear for maximum

transmission of light; the inner layer also has a high degree of

transmission but is diffusive to scatter light to all parts of the

field. Seating is arranged on six levels allowing for six front rows.

It is arranged so that the spectator will enter the stadium at about the

mid-level of seating and proceed either up or down on wide, low-gradient

ramps or escalators.

Since the opinions of the turf experts consulted by the architects

varied somewhat as to the best type of grass to use in the domed

stadium, and since apparently no accurate data were available, it was

decided that a special greenhouse should be constructed at Texas A & M

College Experimental Station in the summer of 1962 and instrument

readings taken. Five kinds of grass were installed and tested over a

range of light conditions. Of the grasses tested, Tiffway Bermuda and

zoysia yielded the best results.

The stadium is cooled and heated using equipment with approximately

6,000 tons of cooling capacity. Altogether 2,000,000 cu ft of air per

min is circulated, of which 250,000 cu ft per min is fresh air. Smoke

and hot air are expelled at the top of the dome. Air-conditioning will

be maintained continuously to avoid buildup of heat and humidity.

Some other interesting problems the architects and engineers worked on were:

Mechanical controls are completely automatic, and necessarily so since

it is a half mile around the building, and to check thermostats would be

a long task. A scanner and a printer to show temperature and other

conditions will be provided. When the proper button is pressed, this

gadget will project a diagram of the piping and duct system with

temperatures at fan discharges and outlets as well as water temperatures

at significant points.

A fire-alarm system will continuously scan detectors throughout the

building, making one complete circle each minute. This scanner will note

the rate of rise, which would indicate when the temperature gets too hot

too fast in any area. An alarm will warn of excessive smoke.

Seating will be arranged on six levels, allowing for six front rows. The

radius point of all rows of seating is approximately second base on the

baseball diamond. For baseball and football all seats face the center of

the playing field. The seating is so designed that spectators will enter

the stadium at about the mid-level and proceed to their seats either up

or down on wide ramps or escalators. Each spectator level has its own

rest rooms and concessions.

Parking will be provided on all sides of the stadium: 20,000 cars and

300 buses will be accommodated.

In addition the stadium will house offices for the stadium managers as

well as other sporting groups. It will have separate press facilities

and dining accommodations for the teams. For the public there will be a

cafeteria dining-room seating 700 people and a gourmet-type restaurant.

Architects on the job were Lloyd

and Morgan with Wilson, Morris, Crain and Anderson. Consultants were

Praeger, Kavanagh and Waterbury. On the dome the consulting engineers

were Roof Structures, Inc. Other consultants included Lockwood,

Andrews and Newnam; I.A. Naman and Associates; Dale S. Cooper; and

John Turney. Fabricator and erector of the steel was American

Bridge. The general contractor was a joint venture of H.A. Lott and

Johnson, Drake and Piper.

Architects on the job were Lloyd

and Morgan with Wilson, Morris, Crain and Anderson. Consultants were

Praeger, Kavanagh and Waterbury. On the dome the consulting engineers

were Roof Structures, Inc. Other consultants included Lockwood,

Andrews and Newnam; I.A. Naman and Associates; Dale S. Cooper; and

John Turney. Fabricator and erector of the steel was American

Bridge. The general contractor was a joint venture of H.A. Lott and

Johnson, Drake and Piper.

Back to Astrodome: Published Commentary

Thirty seven erection towers were

necessary in building Houston's new domed stadium. The tallest tower, at

the center of the structure, was 212 ft. This and the other towers were

salvaged by the erector. The view shows the lamella dome after 19

working days. It is expected that the dome will be completed and ready

for the opening game of the Houston Colts in April.

Thirty seven erection towers were

necessary in building Houston's new domed stadium. The tallest tower, at

the center of the structure, was 212 ft. This and the other towers were

salvaged by the erector. The view shows the lamella dome after 19

working days. It is expected that the dome will be completed and ready

for the opening game of the Houston Colts in April.

Covering over 9 acres of land, the

new

domed stadium in Houston, Texas, offers a playing field and seating

area that is completely covered over. The dome has an outside diameter

of 712 ft. with an overall height of 208 ft. Lamella trusses 5 ft. deep

frame the roof, and there is a total of 2,150 tons of steel in the

350,000 sq. ft. of roof frame, plus a 376-ton tension ring. The stadium

will be completely air-conditioned utilizing equipment with 6,000-ton

cooling capacity to circulate 2,000,000 cu. ft. of air every minute.

Radio-controlled thermostats will be used for the playing area when it is

converted for seating for some sports.

Covering over 9 acres of land, the

new

domed stadium in Houston, Texas, offers a playing field and seating

area that is completely covered over. The dome has an outside diameter

of 712 ft. with an overall height of 208 ft. Lamella trusses 5 ft. deep

frame the roof, and there is a total of 2,150 tons of steel in the

350,000 sq. ft. of roof frame, plus a 376-ton tension ring. The stadium

will be completely air-conditioned utilizing equipment with 6,000-ton

cooling capacity to circulate 2,000,000 cu. ft. of air every minute.

Radio-controlled thermostats will be used for the playing area when it is

converted for seating for some sports.

The stadium is circular in plan and

has six levels of seating.

The stadium is circular in plan and

has six levels of seating. Model testing

Model testing Skylights

Skylights Architects on the job

Architects on the job