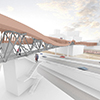

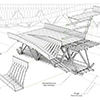

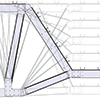

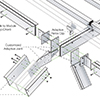

Adaptive Connections is the second-place-winning entry for the 2013 ASCA-AISC Steel Bridge Competition.The post-industrial history and waterfront landscape of downtown Cleveland is characterized by the entangled urban infrastructures resulting from layers of different developmental phases. As Cleveland redefines itself as a thriving contemporary city, the design for this bridge captures the tradition of steel bridge construction and affordable customized fabrication through parametric logic.The urban goal of the bridge is to connect the Cleveland Mall with the cultural and entertainment institutions that line the North Coast Harbor waterfront of Lake Erie. The Mall, designed in the early twentieth century by Daniel Burnham as part of the City Beautiful Movement, presents an axial Beaux-Arts plaza that suggests movement toward the lake. However, this pedestrian connection is severed by the Shoreway, the coastal vehicular freeway, and the railroad lines that connect the city to the regional public and industrial lines. Moreover, the bridge will mark the development for a new intermodal transportation hub. The associated building will be constructed on the same site as the existing Lakefront Station, which, currently isolated, serves only the rail lines. This hub will be a key link between pedestrian, bicycle, rail, and vehicular activity.While the intermodal building serves as a central access point and structural pier to the bridge, access is created at the Mall on the south end, and at the Browns Stadium and Rock and Roll Hall of Fame on the north ends. At the south, the elevated condition of the Mall lends itself as the spring-point for access to the bridge deck. Additionally, the new convention center constructed beneath creates direct entry to the bridge truss level and to the wing of the bridge deck via an existing outdoor mezzanine. At the north, the bridge splits into two separate spans reaching toward the lakefront, where stair-and-elevator vertical entries support the end cantilevers.Cleveland’s history as a major center for steel production in the latter half of the twentieth century provides key infrastructure for the fabrication of the bridge. While originally managing large-scale production of rolled steel, the Rust Belt city has more recently invested in specialized steel production, while an array of unused factory buildings provides opportunities for local labor and production of the bridge’s custom plate steel connections, while the industrial rail link directly below the bridge span provides direct factory-to-site shipping from other regional fabricators of the standard steel extrusions used in the built-up structural members.The design emphasis lies on the variability of a cross-sectional structural and decking system to create a varying topography that hosts an array of opportunities for interaction with the surrounding context. Multi-level passage allows for dynamic experiences along length of bridge, including places of rest (benches), transition from inside (truss) to outside (deck), and views to waterfront, contextual architecture, and the transportation corridors that run below.The parametric structural bay is conceived through a combination of standard stock steel extrusion members and custom, water-jet-cut connection plates. By sandwiching the plates, complex bent plates allow for geometric variability with minimal customized steel and provides repeatable, varied connection details for simple, efficient, shop-built construction for rapid on-site construction. Strings of purlins, hosted by the structure, support the varying decking that wraps across these bays. The decking is comprised of strips of bent plate steel, articulated to meet the programmatic and experiential intentions of the bridge design. Along the outer wings, the decking transforms into seating benches. On non-horizontal stretches, the decking is twisted to reflect the gradation with the slope of the surface to provide open views through to the surroundings.

© 2013 MARK POTHIER