Geomechanics & Geotechnical Engineering Program

Why is this branch of knowledge known as geotechnical

engineering? I felt more like to use the term geoengineering.....

(8/29/2006)

Soil Mechanics/Geomechanics is sometimes confused as Geology or Soil Science

[but there are similarities with geological engineering]. In soil

mechanics, we study and characterize the properties of soils that

are relevant for engineering analysis or design. We study the behavior

of

soil, up to failure, due to external or internal loading. Different

natural

or man-made soil structural systems, ranging from very

traditional to

recently developed ones, are studied. I have a bit

of

writing

about geotech to share with you.

The geotechnical research at Columbia University is directed toward laboratory

testing, theoretical analysis, and verification of theories and experimental

works. The

Burmister

Geotechnical Laboratory, a state-of-the-art research and teaching laboratory

for soils, is located in Room 706, MUDD Building.

We have installed a state-of-the-art 200g geotechnical centrifuge, which enhanced greatly our experimental research capability.

The Burmister Lecture and DJ Memorial Lecture are our annual events. Biot Lecture is also closely related to geomechanics.

Geotechnical Laboratory

(since 1933)

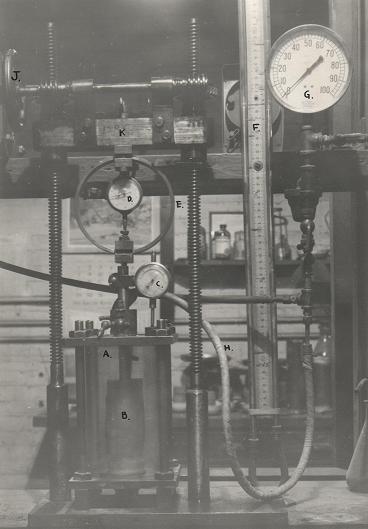

The Geotechnical Laboratory was established by Prof. Burmister in

1933 as one of the first soil laboaratories in this country. It is now equipped

with several unique

apparatus

for advanced soil testing and research.

Soil Mechanics at Columbia 1933-1963 (Page 1, 2 , 3)

Soils Laboratory Class:

The state-of-the-art laboratory apparatuses are designed and fabricated

with direct input from Hoe Ling and his

research collaborators

. The laboratory is housed with an automated

Plane Strain device

and and also a

triaxial device

, both of which allow stress path testing of soils at both drained and undrained

conditions (

basic concept of automation

). A large

direct shear device

is also available for studying shear strength of soils and interaction properties

between soils and geosynthetic materials. The triaxial and direct shear devices

accommodate specimen of several different sizes. Currently, an integrated

system is being developed for the instrumentation and control of these devices.

(Visit the parent or

sister apparatuses

at the University of Tokyo)

Heavy-duty model tests may be conducted using

MTS testing machine

as well as the 600,000 lb.(2670 kN) capacity

universal testing machine

. Test on large-scale retaining wall models would be possible using this

apparatus. [Wide-angle picture of the two machines].

Large specimen of gravels, of diameter 31 cm, is possible using the MTS device with our testing procedures.

The Laboratory is also equipped to conduct standard soil testing, such

as consolidation, permeability and compaction tests. We are also capable of

preparing clay specimens by resedimentation using a large consolidometer.

Model Test: A

sand box

is available to conduct model tests. This box allows pressure or suction

to be applied to the soil foundation under saturated conditions. A displacement-controlled

jack is attached to this sand box. A unique

sand hopper

is available to prepare the foundation and slope for small-scale model testing.

The hopper creates automatically uniform sand foundation under very precisely

controlled conditions, such as the falling height and opening size. This

sand hopper is also used to prepare uniform foundation of different densities

for liquefaction testing in the centrifuge.

Take a look at some of unique equipments again.

Click here

Large-scale tests are conducted for geotechnical earthquake engineering

related to the performance of pipeline under liquefied soils and of slope

stability.

Research Activities

check the main page and more activities with the centrifuge

research topics:

- Slope failure in the centrifugal field and methods of slope stability analysis

- Lateral impact of pile (simulating structural protection in the marine environment)

- Performance of reinforced soil retaining wall (using the centrifuge and numerical analysis)

- Reinforced soil retaining walls with geocell facing - earthquake loading

- Constitutive modeling of soils and numerical analysis

- Behavior of soil mixtures

- Soil-structures interaction behavior

- Debris flow and associated disaster management

- Fluid flow in bones (Biomedical)

Past research topics:

Seismic Performance of Geosynthetic-Reinforced Segmental Block Walls:

Large-scale shaking table tests that are heavily instrumeted. The world

tallest wall of its kind under earthquake shaking. Tests conducted using

the facilities in Japan. We don't want to be associated with scale effects, so they are FULL SCALE tests!

Lateral Resistance of Pipe Pile: Full-scale tests are being conducted in

Carleton Laboratory to determine its lateral resistance until and post yielding.

A sand box, 14' tall, 6' by 4' is fabricated to accommodate a 8"-diameter

steel pipe. Lateral Loading Test of Steel Pipe Piles

Embedded in Sand (unpublished report)

Soil Constitutive Modeling: Research has been conducted to develop

a simplified anisotropic bounding surface model based on the critical state

concept. The model was extended to consider viscoplastic behavior of clay.

The model has bene validated with test results for different clays, normally

consolidated and overconsolidated, and different modes of shearing. The ultimate

goal is to develop a procedure capable of simulating the behavior of soil

deposit subject to long-term loading.

A sand model was also developed by modifying the generalized plasticity

model to include pressure-level effects and cyclic hardening behavior. The

model is being used for the numerical analysis of soil structures.

Debris Flow: We started to get into this area with a great interest

in the debris flow hazards in Taiwan. The study will be on the mechanics

and simulation of debris flow, and hazard mapping.

Liquefaction, Flotation of Pipelines and Mitigation: Joint research has been conducted

using the

three-dimensional shaking table

at NRIAE. Recently,

a large laminar box

(inner dimensions: 35.5 cm x 72 cm x 35.5 cm) has been fabricated with the

liquefaction tests conducted using the

centrifuge facilities at the Rensselaer Polytechnic Institute

. Theoretical studies were also made through the numerical procedures using

a coupled stress-flow dynmaic finite element approach.

Liquefaction hazard studies. Effective Stress Response and Liquefaction

Potential for xxxxxxxxx (classified report)

Permanent Displacement of Geosynthetic-Reinforced Soil Retaining Walls:

The reinforced soil retaining wall system has been studied through experimental

and analytical methods. The cyclic behavior of geogrids has also been studied.

A cyclic model for geosynthetic, based on bounding surface elasto-plasticity

has been formulated and implemented for numerical analysis.

A preliminary study on the seismic performance of GRS-RW under a joint

collaboration with the Tokyo Institute of Technology, using the centrifuge

shaking table tests, was initiated two years ago. A finite element proceudre

is verified with the test results.

Information on above two projects are available at the

centrifuge page

.

We also made separate trips to Taiwan and Turkey to investigate the performance

of reinforced soil structures during 1999 Ji-Ji and Izmit earthquakes. Several

reinforced soil structures failed during the earthquakes. A project funded

by the National Science Foundation is in progress to validate our design

methodologoes with reference to the structures that failed. Meanwhile, an

International Workshop was held for advancing the knowledge on this issue

at Columbia University on Oct 30 & 31, 2000.

Some information are available on this page

Deformation of Modular Block Geosynthetic-Reinforced Soil Retaining

Walls: A numerical study related to the performance of geosynthetic-reinforced

soil retaining walls, with modular block facing, has been completed. The finite-element

procedure employing M-CANDE was verified with the field performance of a

full-scale geosynthetic-reinforced soil retaining wall constructed at the

Public Works Research Institute, Ministry of Construction, Japan. A series

of parametric studies were also conducted to investigate the various properties

of geosynthetic reinforcement, foundation and backfill soils, block interaction,

etc., on the overall performance.

Performance of Pavement Reinforced with Geosynthetic: Geosynthetic

materials are used in the flexible pavement system. Static and dynamic tests

were conducted to investigate the performance of pavement-geosynthetic system.

The finite-element procedure is used to simulate the test results. Upon successful

modeling of the soil-pavement system, a series of parametric studies were

conducted.

Waste Containment System: We also conduct studies on the geoenvironmental

engineering issues: settlement of municipal solid waste landfill, seismic

stability and permanent displacement of landfill cover system, soil-geomembrane

interaction, sand capping of contaminated submarine sediments.A series of

shaking table tests related to the stability of landfill cover soil have

been conducted at Dalian University of Technology. We modified the direct

shear box for studying the interaction properties between cohesive soils

and geomembrane. A tilting table test was manufactured for studying the interaction

properties at very low confining pressure.

International Collaboration: We are promoting actively

international research collaboration. Over the past several years,

Geotechnical Laboratory has collaborated closely with the Japanese

industries, universities as well

as the governmental research institutes from different ministries, and

also

with a few other countries. International students from Japan, Italy,

Spain, among other countries, have joined us in the graduation research

projects.

Past research may be found in the list of

publications

.

December 20, 2009