| |

Title |

| |

|

CAREER: Energy in sustainable infrastructure – multi-scale/physical approach to a novel hybrid solar roofing panel

|

| |

| |

Participants |

| |

|

- Huiming Yin

- Lingqi Yang (Ph.D. student)

- Xin He (M.S. student)

|

| |

Project Quad |

| |

|

|

| |

| |

Summary/Objectives |

| |

|

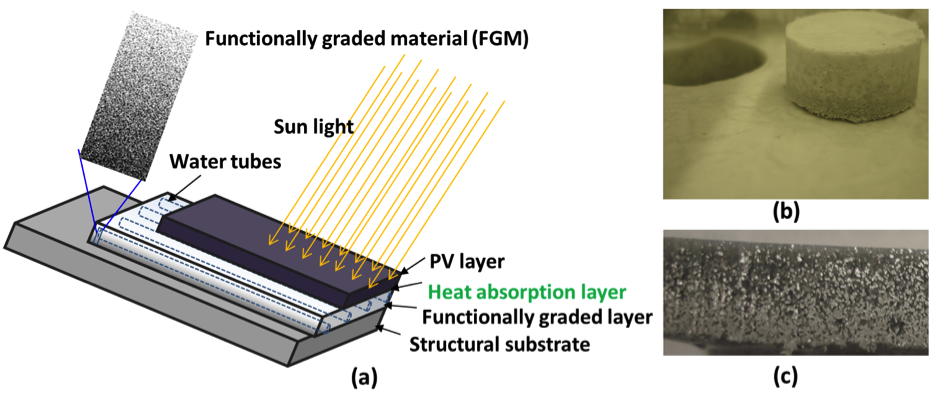

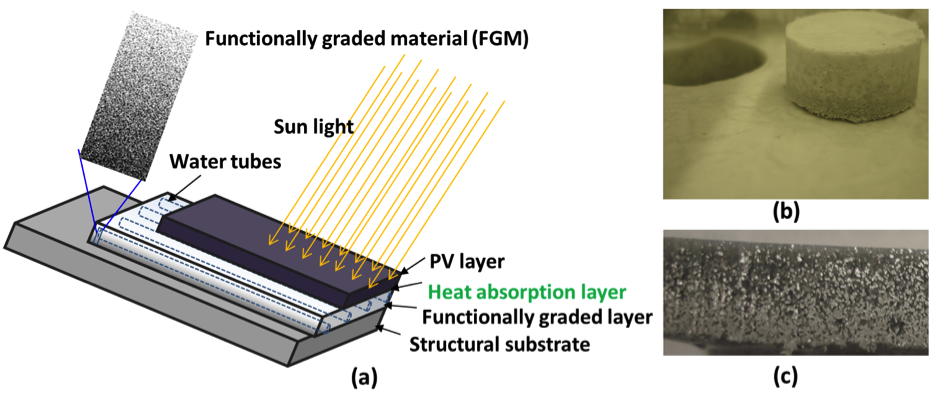

The objective of this project is to develop a novel hybrid solar roofing panel with a light-weight functionally graded material (FGM) layer that has varying thermal conductivity in the thickness direction as in Fig. 1(a). The heat is gradually transited from a well conductive side attached with a PV solar cell (laminated by a protective layer) to another highly insulative side bonded to a structural substrate. The water flow through the FGM layer cools down photovoltaic (PV) cells and harvest the solar heat. In the manufacturing of the FGM, Al and HDPE powders are first mixed in a fluid. Due to the different densities and sizes of particles, the powders fall down to the bottom of the container at different velocities and thus form a graded microstructure. After draining out the fluid, one can obtain the functionally graded powder mix as in Fig. 1(b). Sintering the mix, we can obtain a functionally graded composite as in Fig. 1(c). In the computation aspect, dissipative particle dynamics is adopted to simulate such manufacturing process at meso-scale to improve the design of the FGM layer. The vibration effect on the final formation of the FGM layer will be investigated quantitatively.

|

| |

| |

Approach |

| |

|

Experiment:

|

| |

|

- Mix Al powder, HDPE and ethanol together.

- Place the Al mold on the center of the vibrating table, then put two sheets of aluminum foils and the Aluminum pipe in the bottom of the mold.

- Dump the mixture into the mold and vibrate the mold. This will make the mixture has a gradual sedimentation.

- Leave the mixture and the mold on the vibration table overnight for fully drying out.

- Place the specimen in a vacuum oven; raise temperature to 170 0C with vacuum condition for 30 minutes.

- Put the Al cover onto the specimen. Then raise temperature to 170 0C with vacuum condition for 15 hours.

- After the whole set up has cooled down, remove the mold and uncover the Al foil, and we can get the FGM with good gradient.

|

| |

|

Simulation:

|

| |

|

- Use dissipative particle dynamics to simulate single particle sedimentation

- Simulate many particles sedimentation

- Study the vibration effect on the FGM layer formation

|

| |

| |

Results |

| |

|

Experiment:

|

| |

|

- Our group has made several samples, but the gradient formation is either not obvious or major defect is observed. For example, there are bubbles in the sample. Secondly, we can’t control the gradient very well.

|

| |

|

Simulation:

|

| |

|

- A parametric study is completed to establish a guide for choosing DPD force parameters toward single particle sedimentation

|

| |

| |

Publications |

| |

|

- Parametric Study in Dissipative Particle Dynamics Simulation toward Particle Sedimentation, 2014, Phy. Review E., submitted

|

| |