Assembly of Nanostructured Materials and Devices

This effort focuses on the

directed and self assembly of nanomaterials from nanocomponents. This includes the patterned and unpatterned films and of device structures of

nanocrystals by using electrophoretic deposition and of carbon nanotubes and of nanowires by dielectrophoretic deposition. The Herman group is also interesting in the optical, electrical, and mechanical properties of these nanostructured materials and arrangements.

Also, see

publications, including #96, 100, 109, 113, 114, 116, 119, 124, 126, 128, and 130-138.

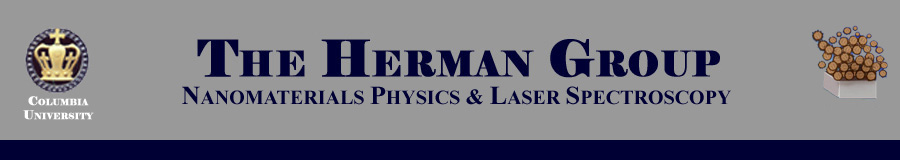

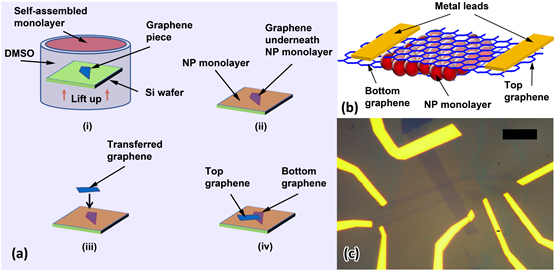

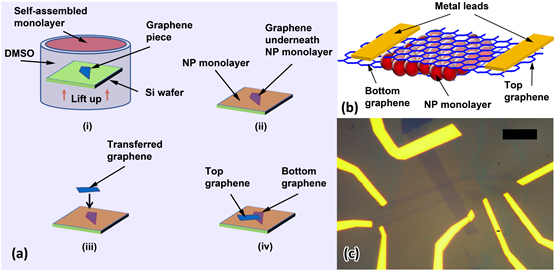

Fabricating Quantum Dot Monolayers Sandwiched Between van der Waals Monolayer Electrodes

Using methods to form order monolayers of quantum dots on a liquid surface,

the Herman group made sandwiches of a monolayer of CdSe quantum dots (or nanoparticles) between two graphene layers,

as shown in the below figure. This is a new type of vertical heterostructure made of nanocomponents, which can provide

new functionality.

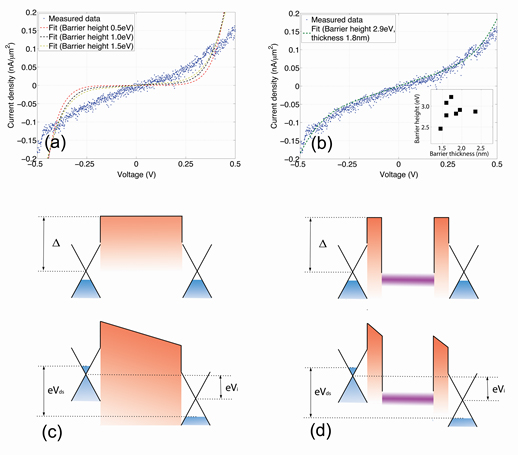

This heterostructure has an tunneling type of I-V behavior (as seen in the below figure).

For more, see

“Electronic Transport in Nanoparticle Monolayers Sandwiched Between Graphene Electrodes,”

C. Lu, D. Zhang, A. van der Zande, P. Kim and I. P. Herman,

Nanoscale 6, 14158-14162 (2014).

Back to top

|

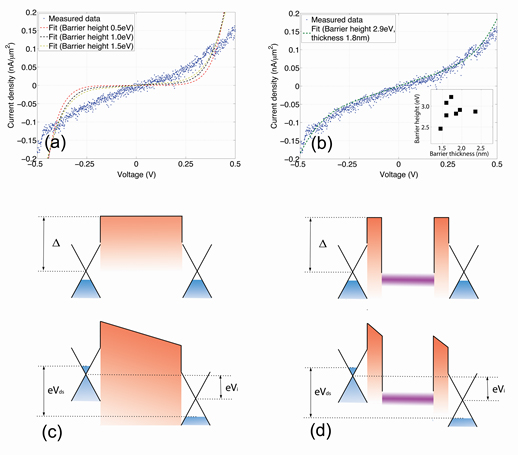

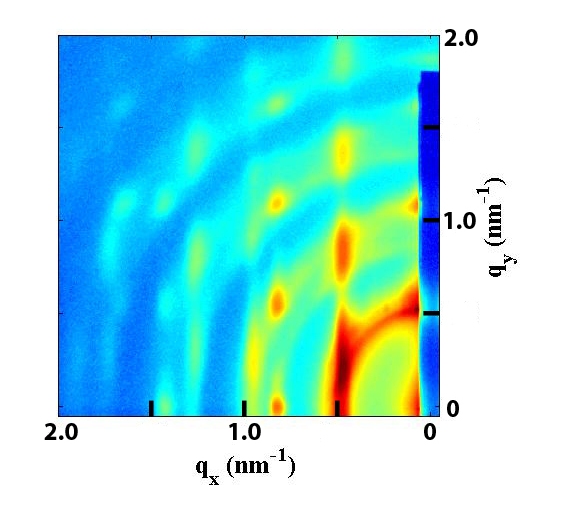

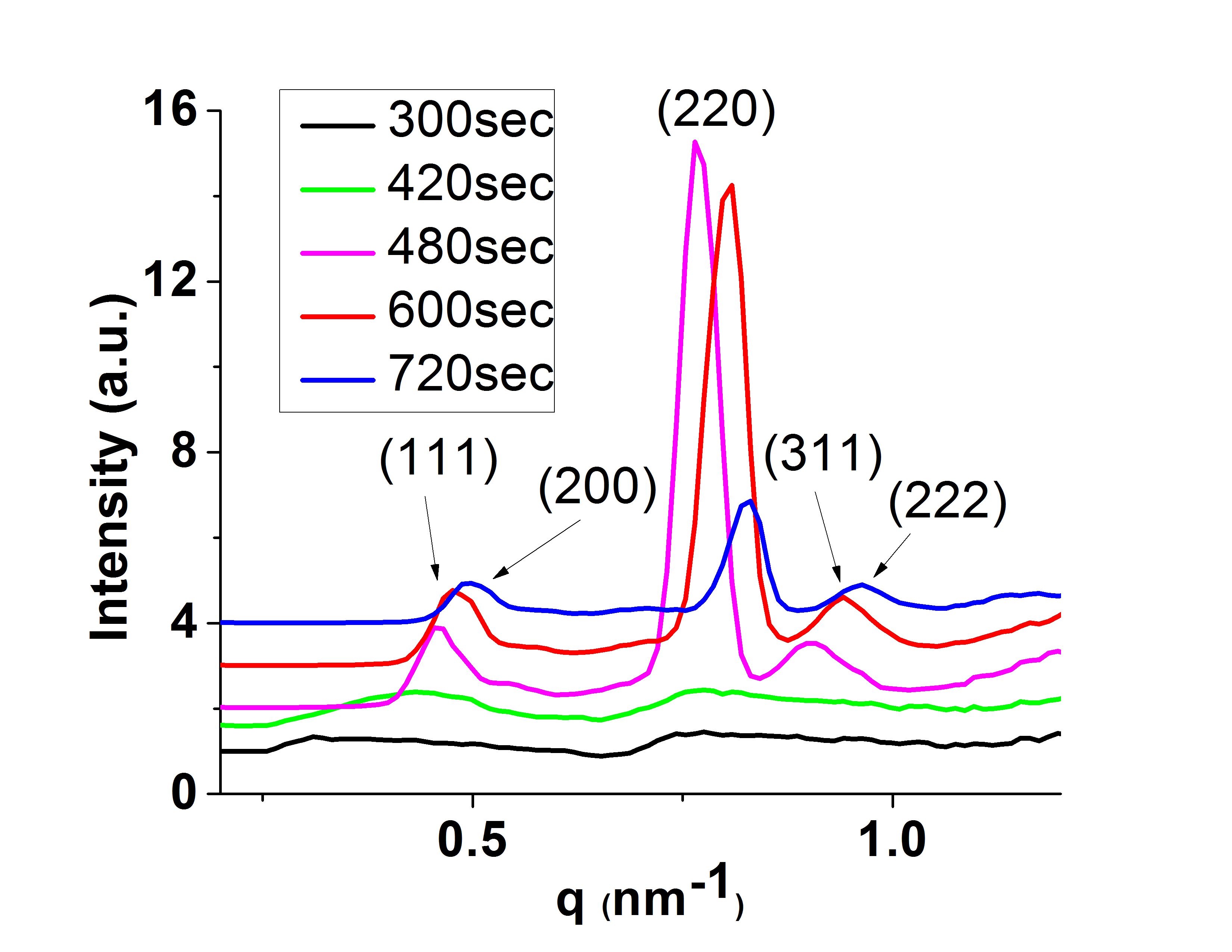

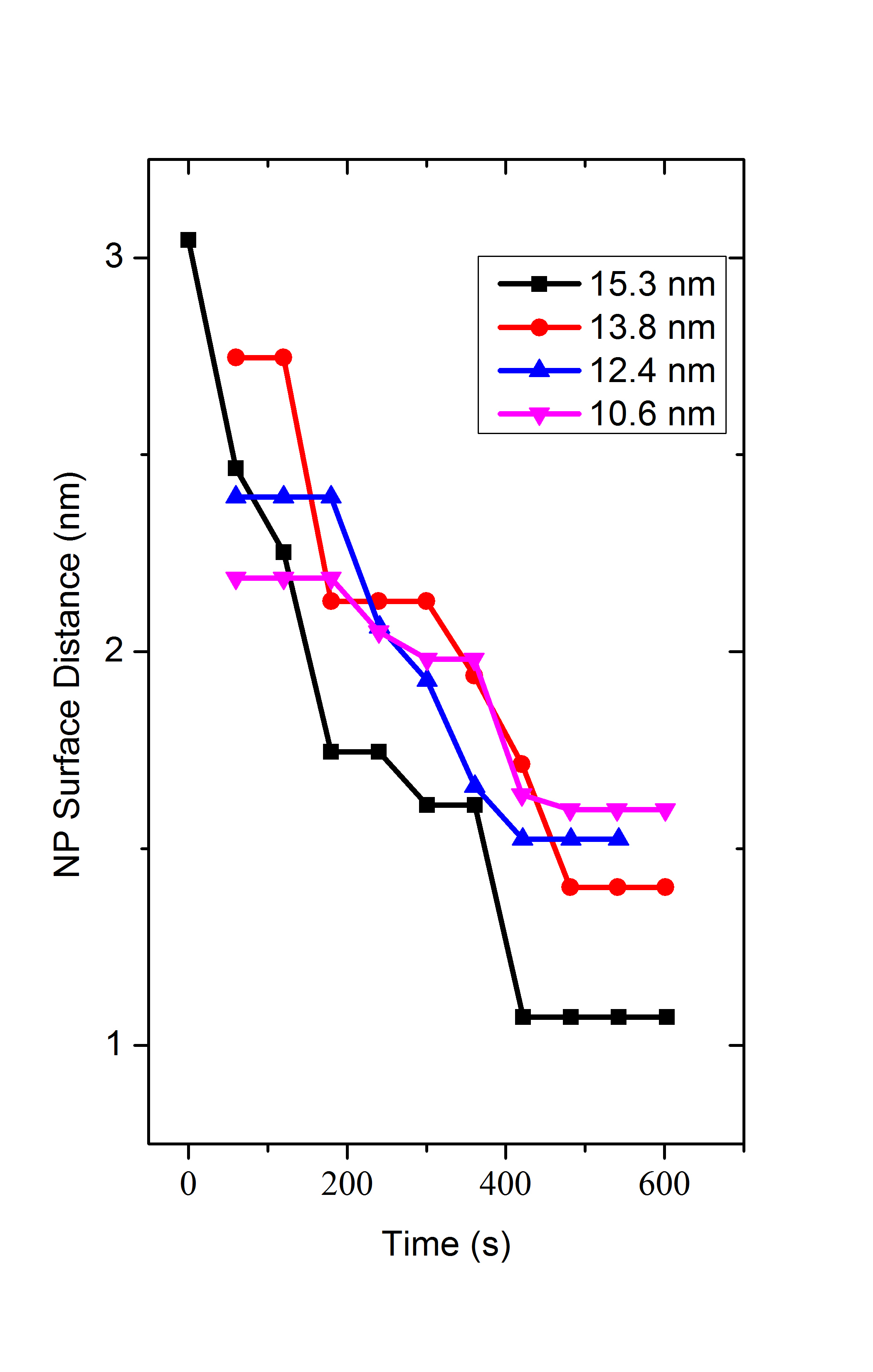

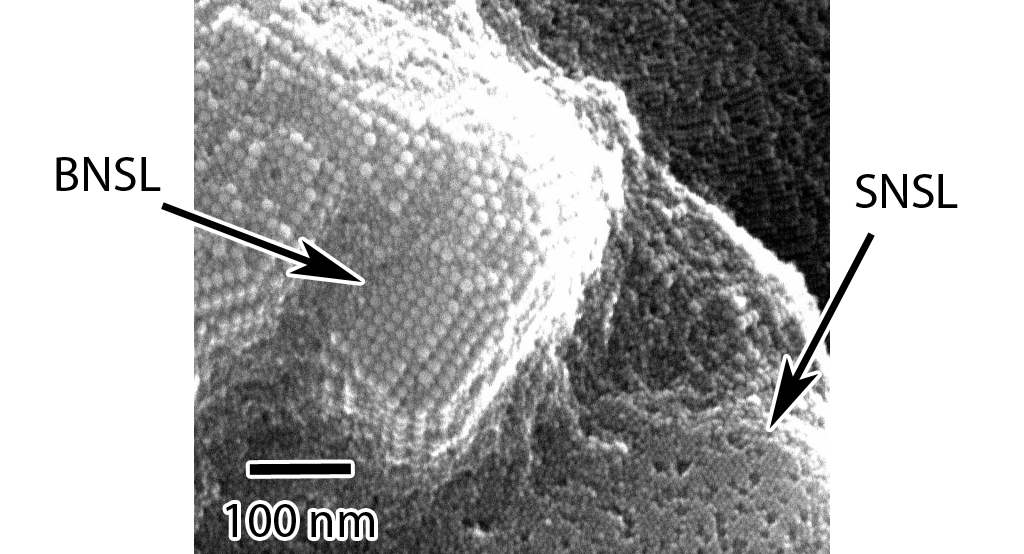

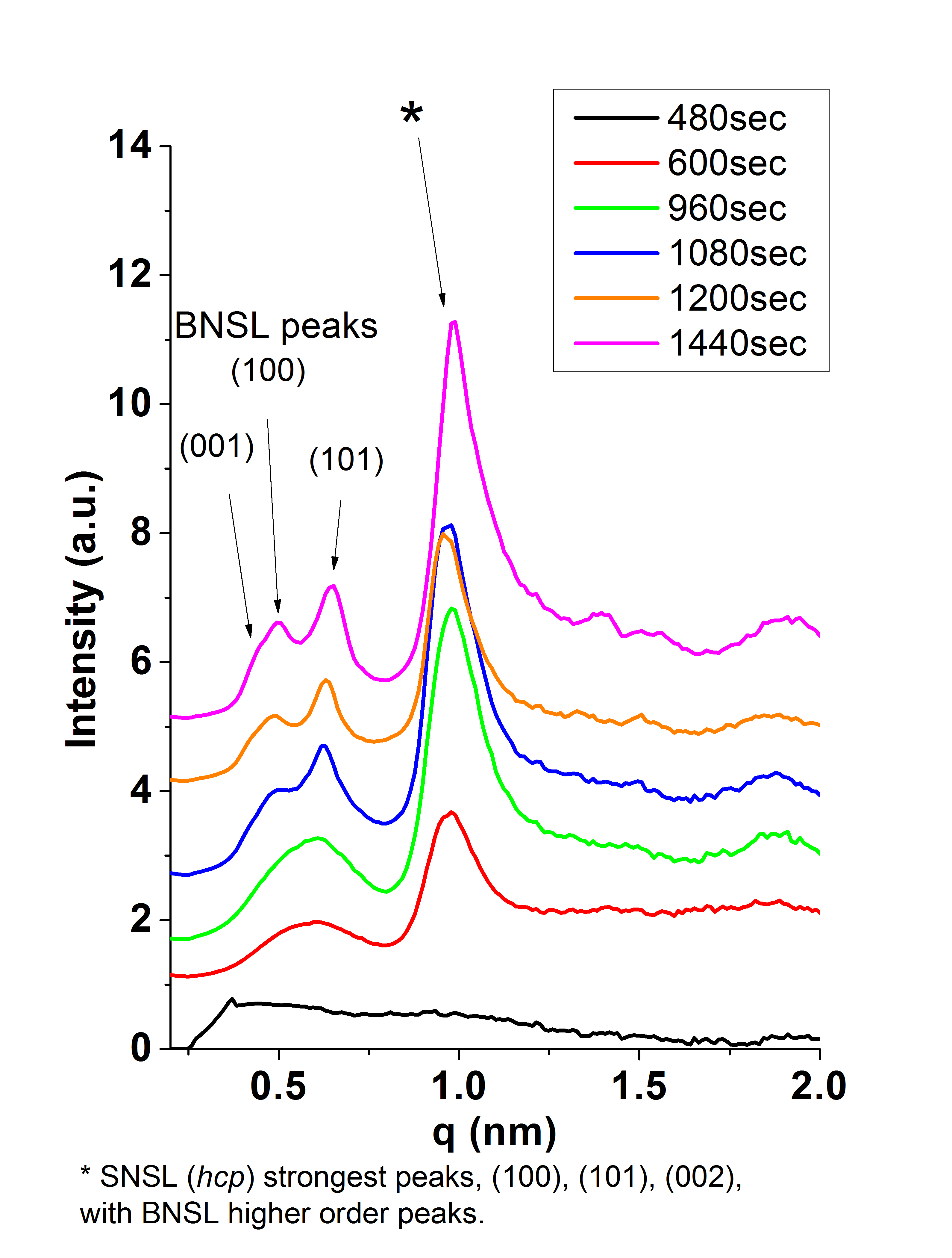

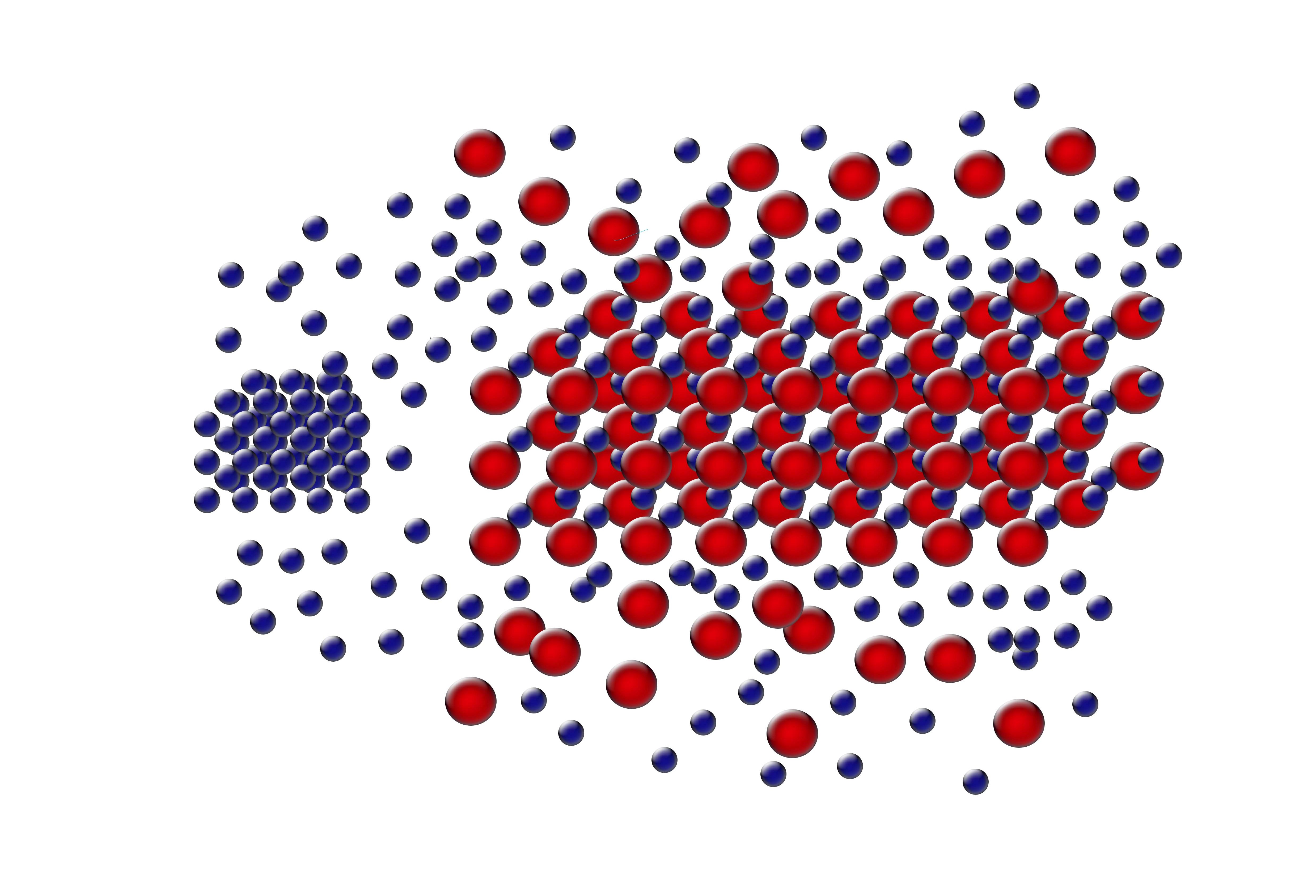

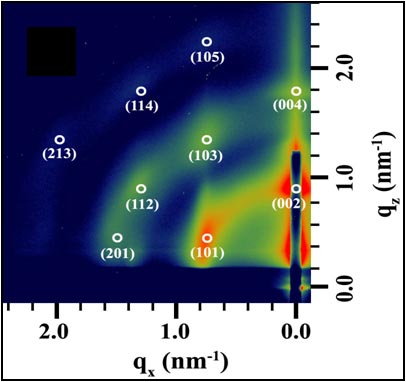

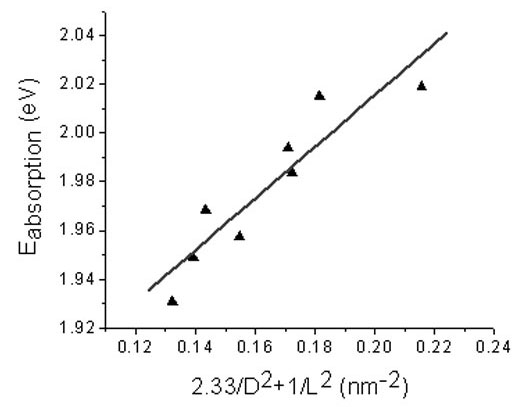

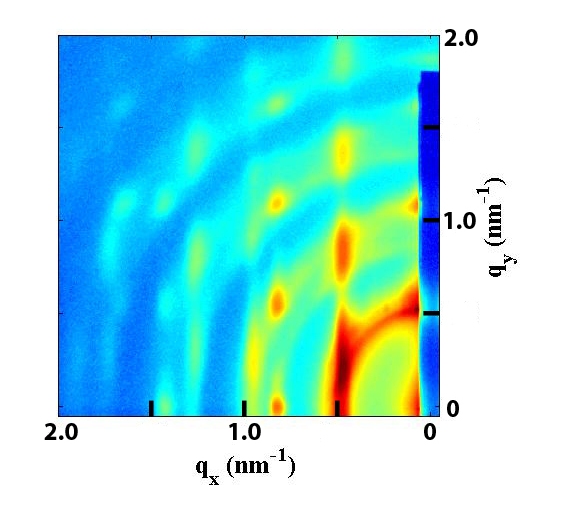

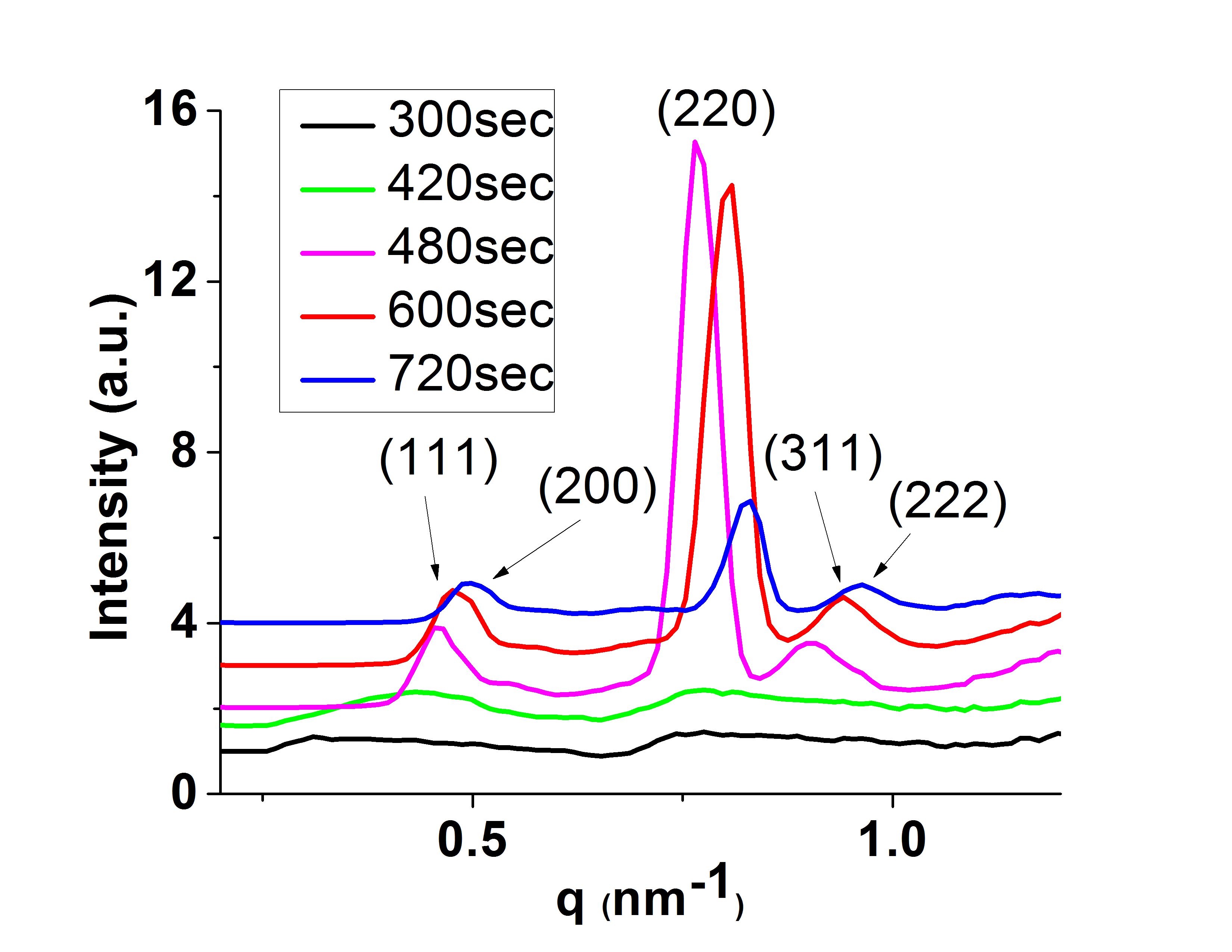

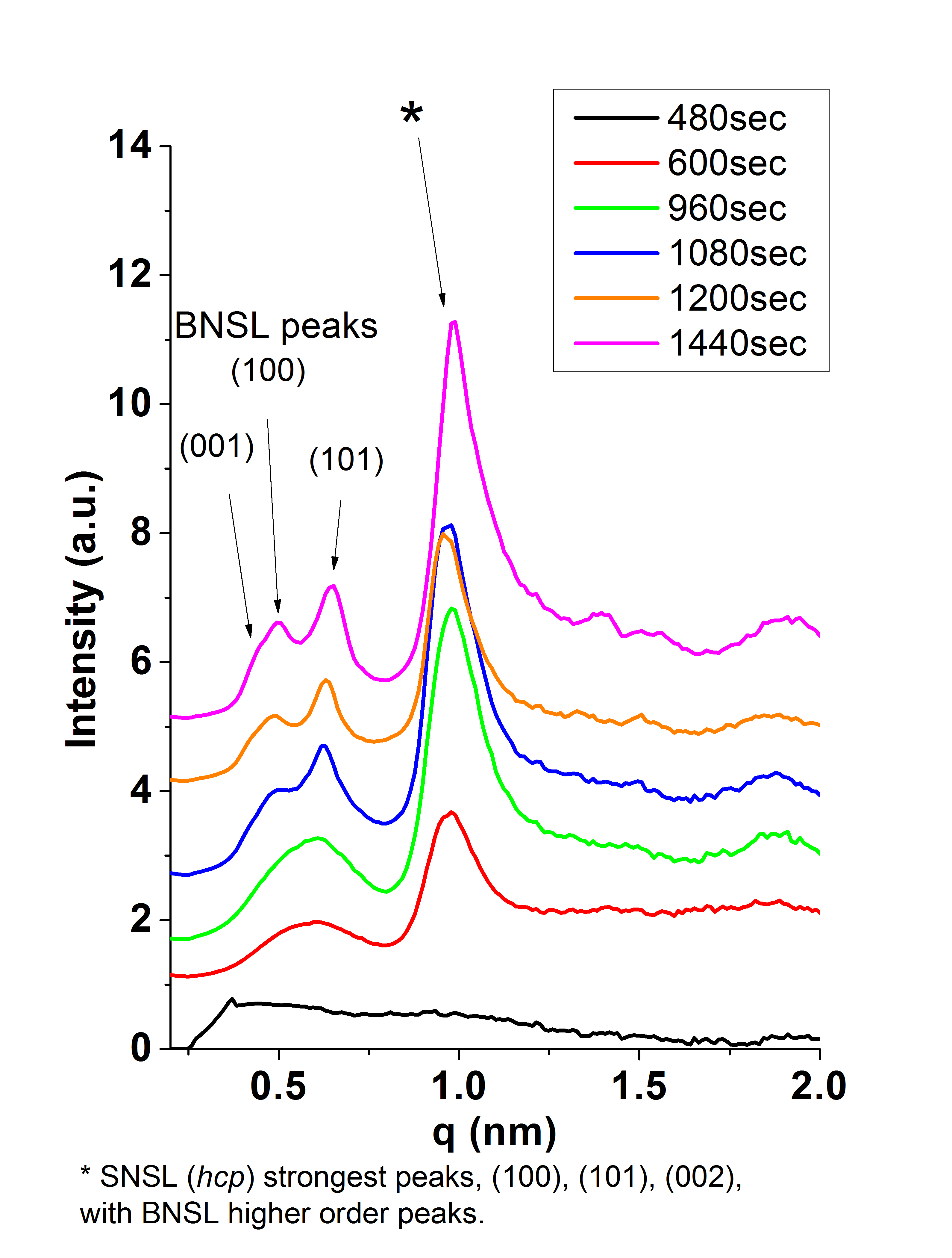

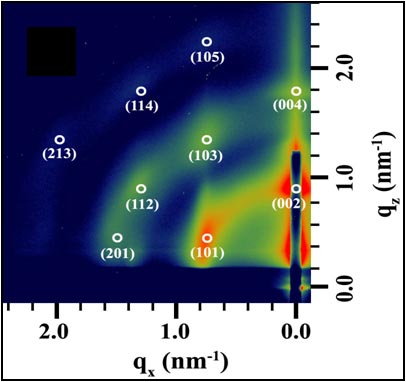

SAXS Monitoring Growth of Thick Single and Binary Nanoparticle Superlattices

Using small angle x-ray scattering (SAXS) at the

Brookhaven National Laboratory

the Herman group has followed in real time the kinetics of the growth of ordered

3D NP superlattices (SLs, SNSLs) (of one size of iron oxide NPs) and binary NP SLs (BNSLs)

(of two sizes of iron oxide NPs)

in solution are understood by combining controlled solvent evaporation.

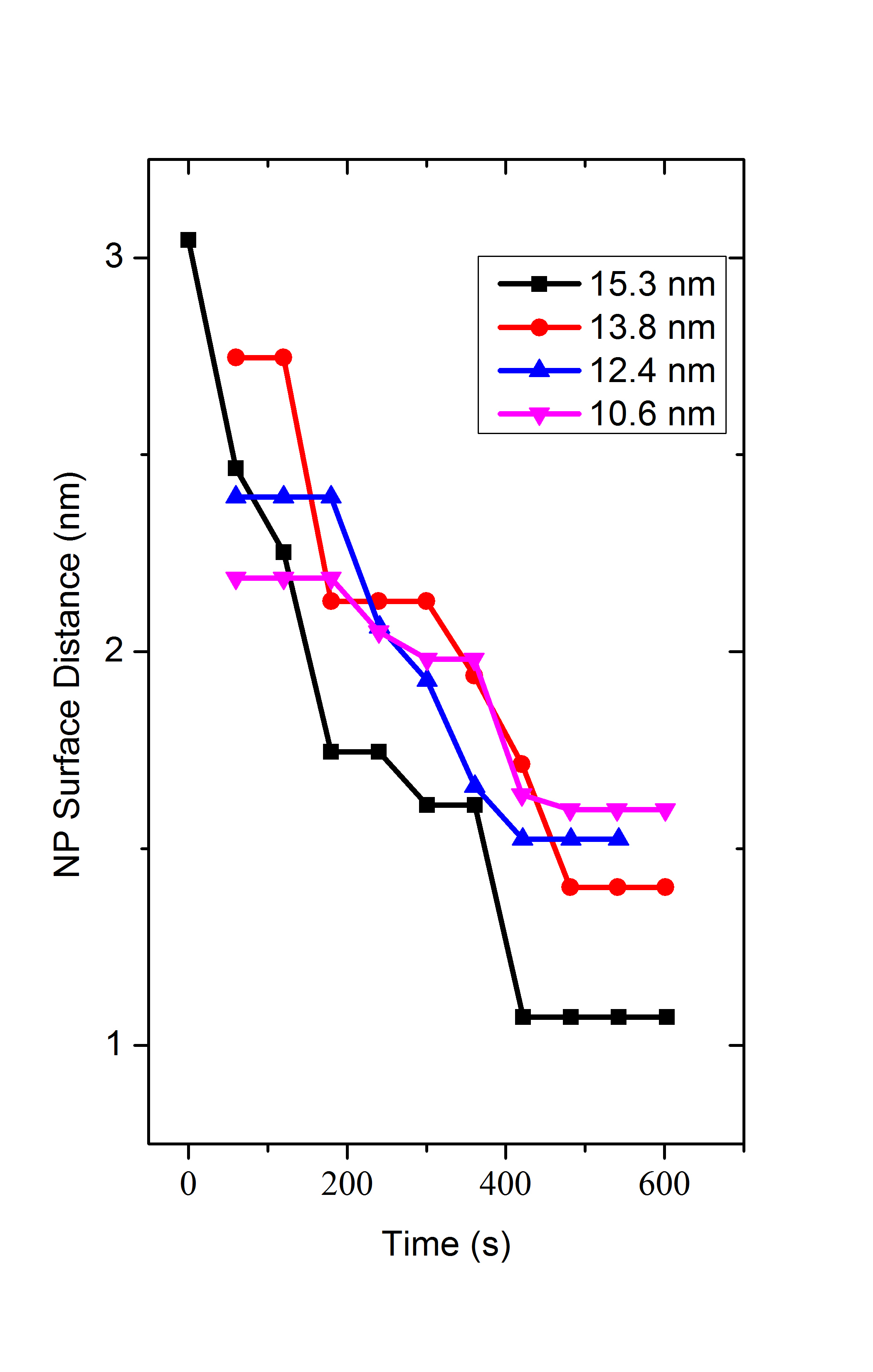

We have learned that

the larger the NP the farther apart are the NPs when

the SNSLs begin to precipitate and the closer they are after ordering, as seen in the below figures,

which we have explained

by using a model of the energies of interactions betweent the NPs.

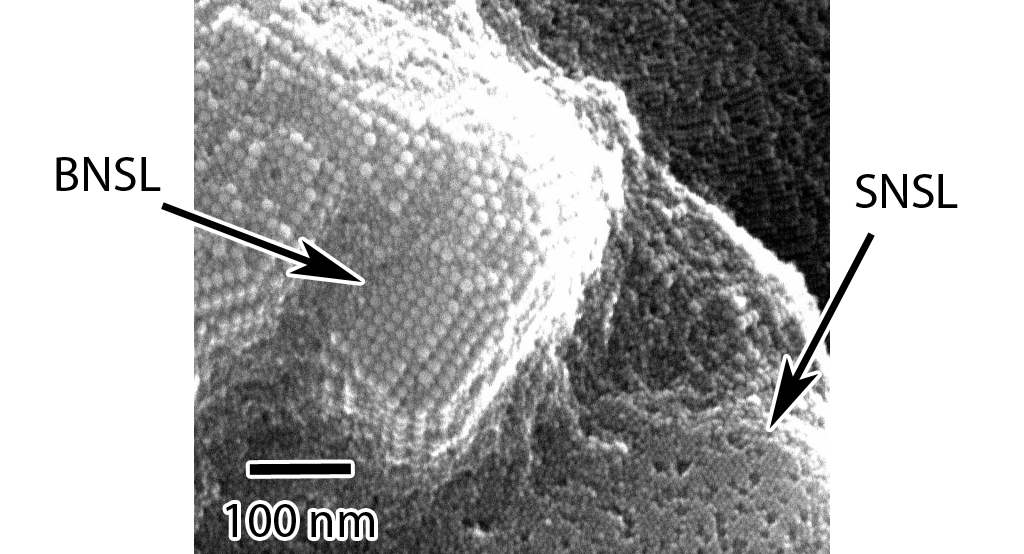

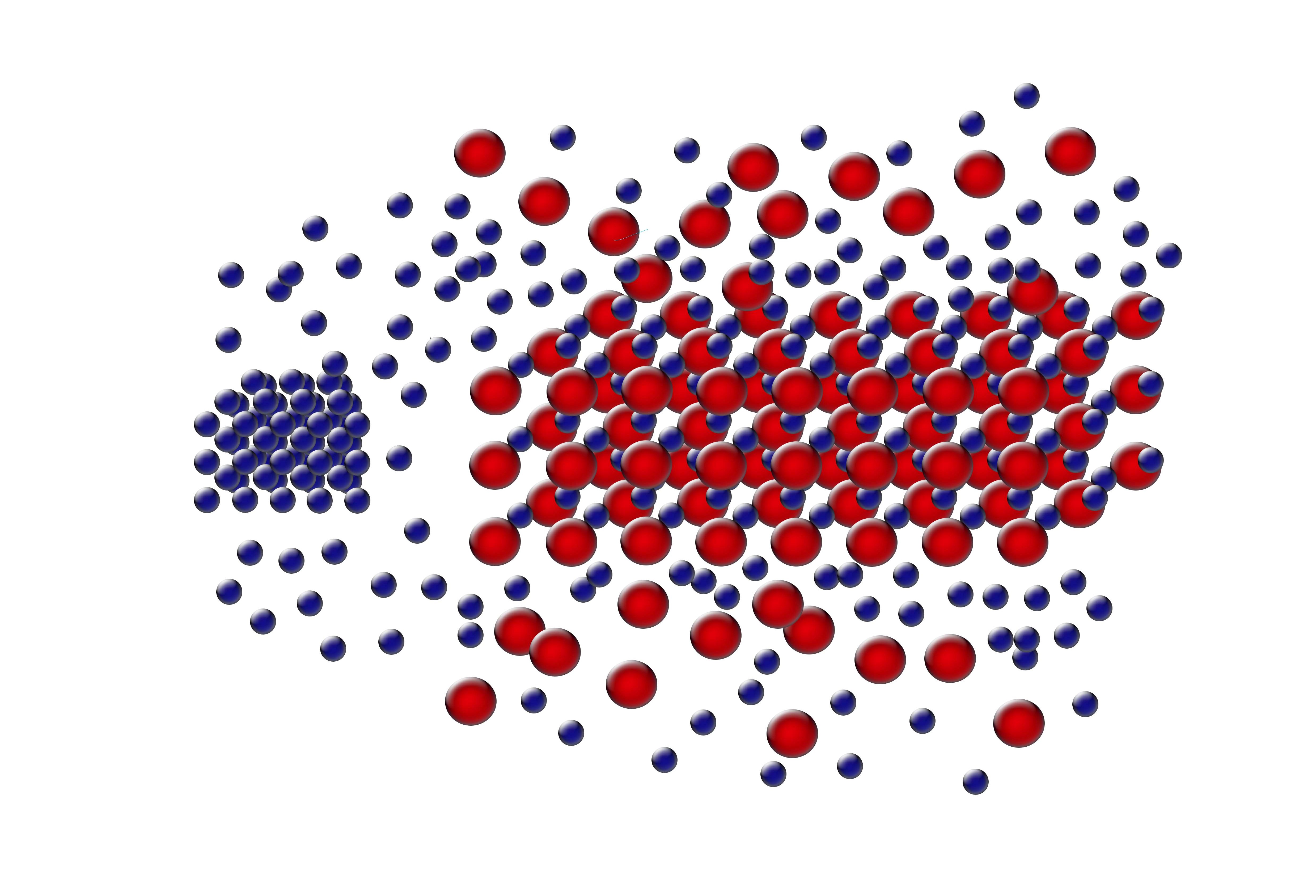

When forming BNSLs of two different sized NPs, the NPs that are in excess of that needed

to achieve the final BNSL stoichiometry are expelled during the BNSL formation

and these expelled NPs can form SNSLs (as seen in the below figures).

For more, see

“Resolving the Growth of 3D Colloidal Nanoparticle Superlattices by Real-time Small Angle

X-ray Scattering,”

C. Lu, A. J. Akey, C. Dahlman, D. Zhang, and I. P. Herman,

J. Am. Chem. Soc. 134, 18732–18738 (2012).

Back to top

|

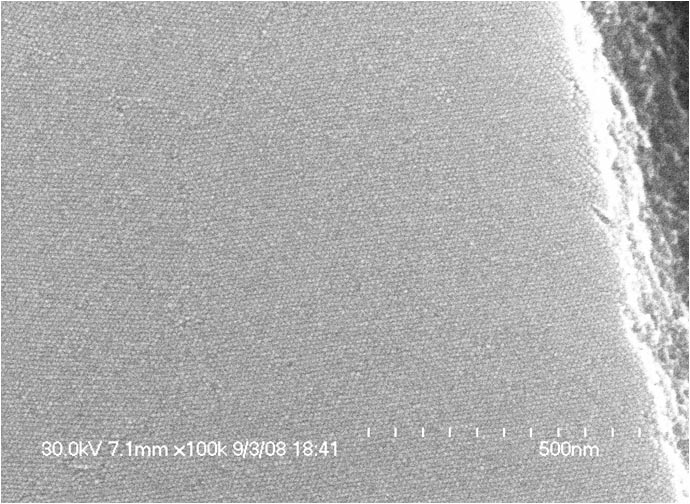

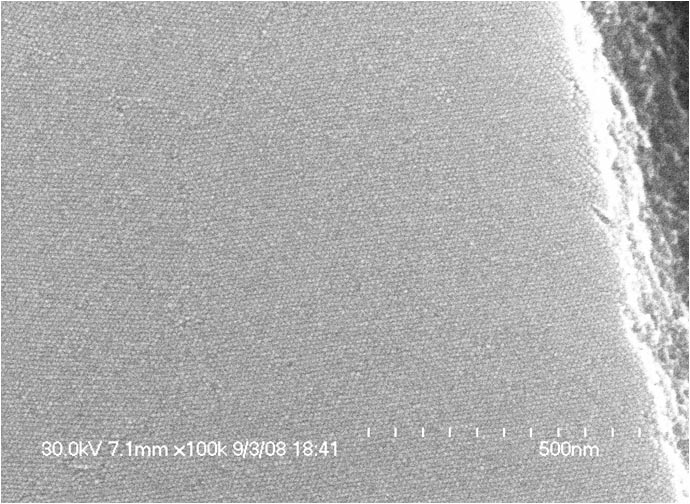

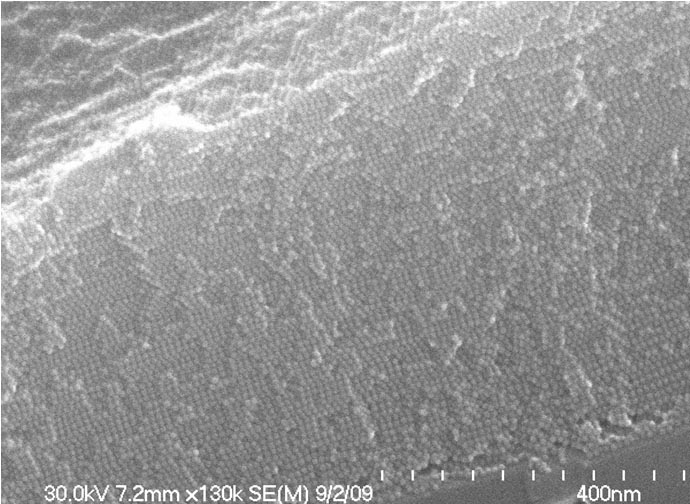

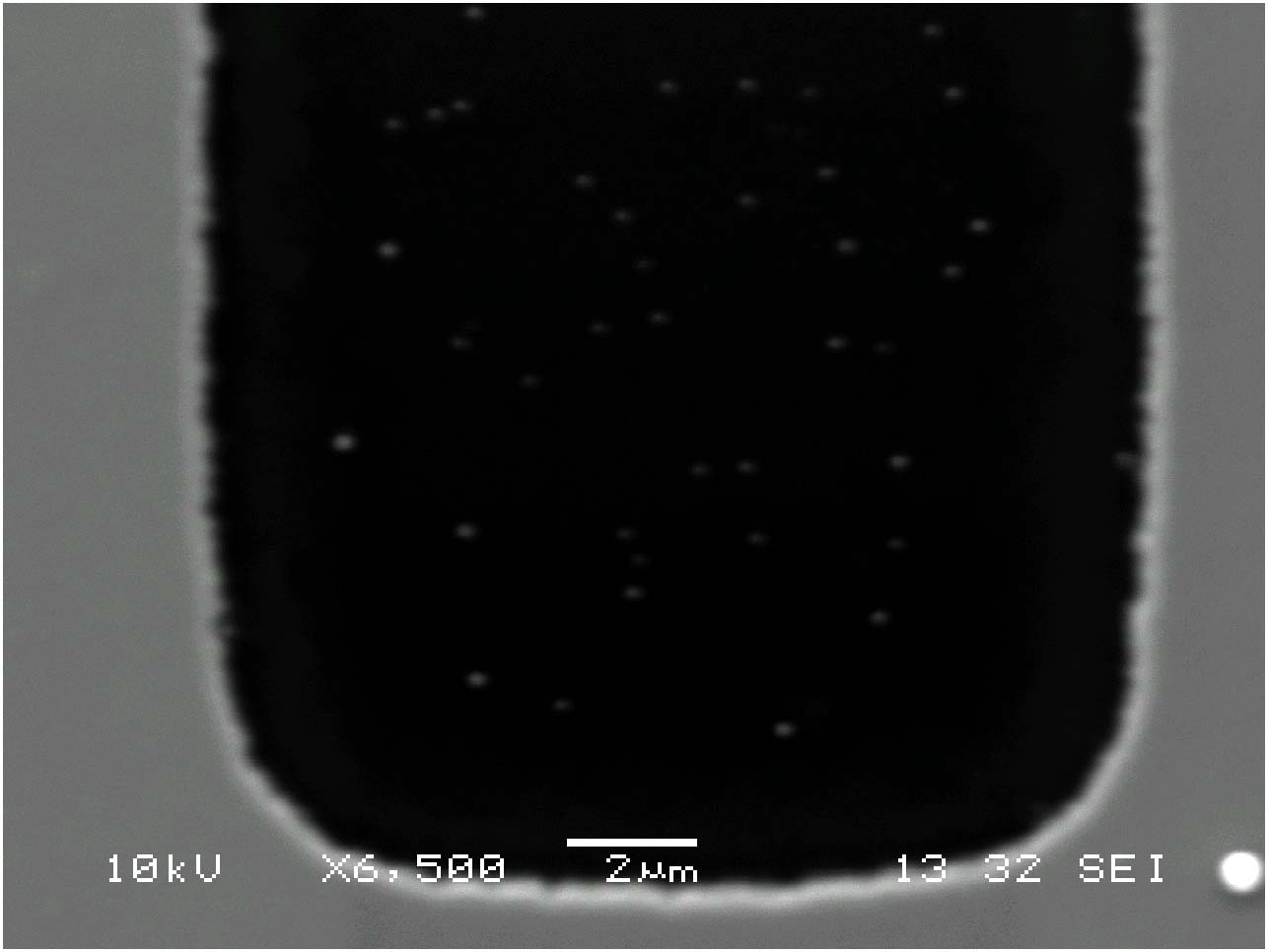

Precisely Placed 100-Layer Thick Nanocrystal Superlattices

The Herman group has developed a method to form 100-layer thick supercrystals of nanoparticles

at lithographically-determined sites using a two-solvent microfluid flow method. These micrometer-dimension supercrystals

form as a result of flow from a reservoir to a channel (due to capillary flow) and subsequent controlled drying.

Previously, very few layered-superlattices could be formed on surfaces and supercrystals could be formed only after drying in beakers.

These new materials open the prospect of cooperative optical, electrical, magnetic and magenetic properties.

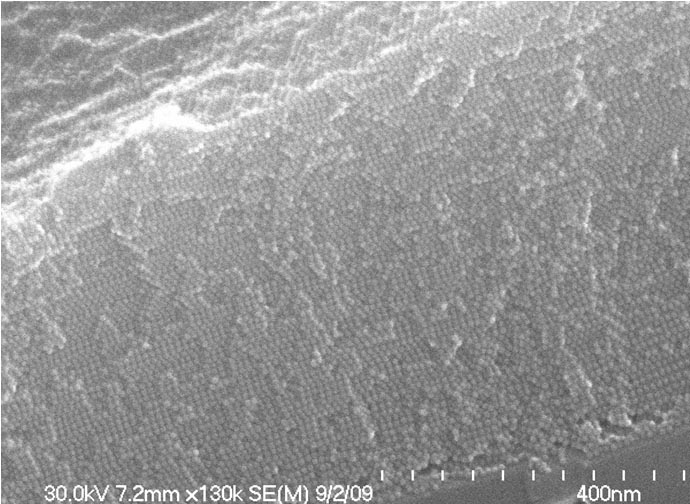

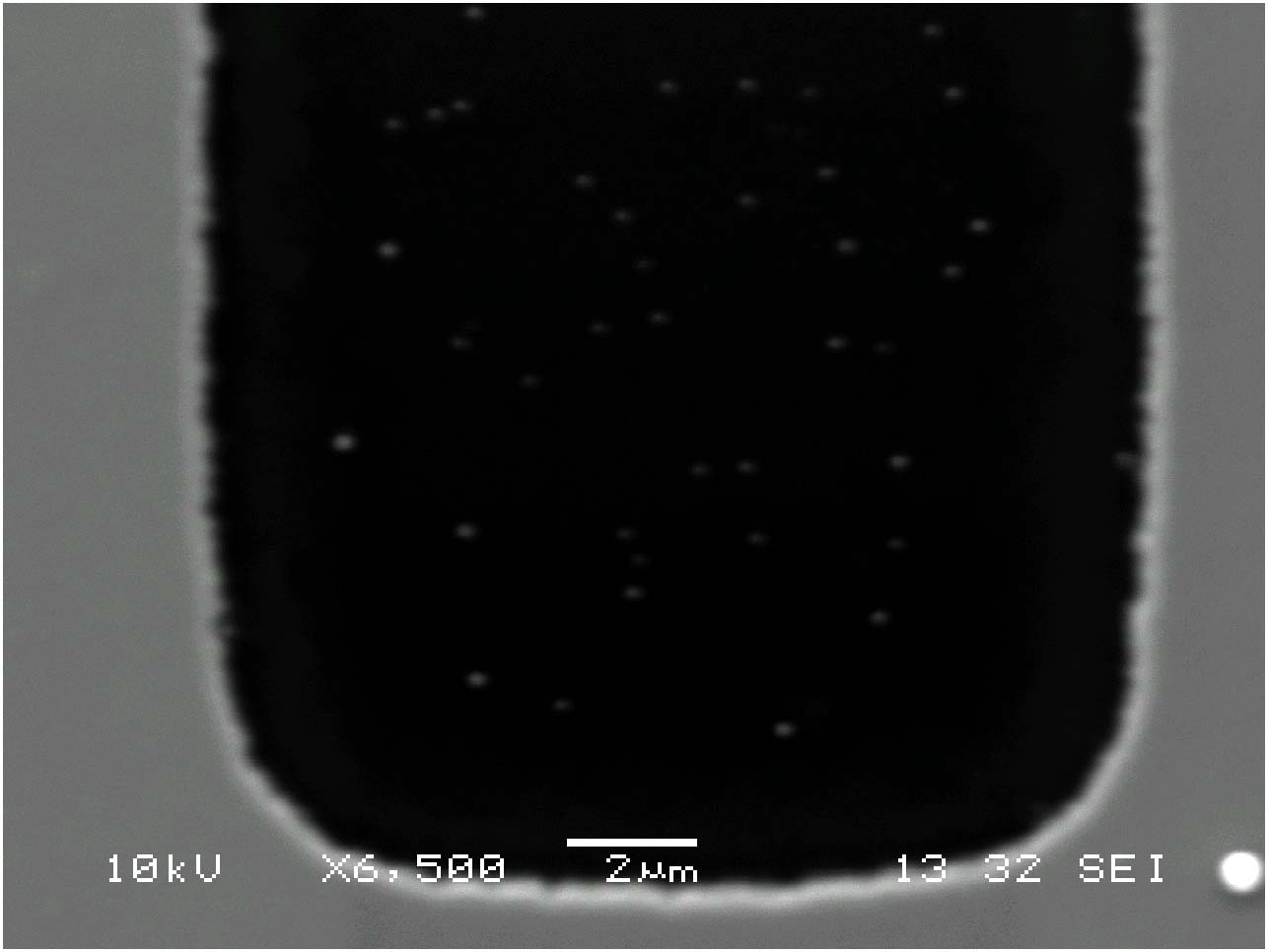

The left SEM shows the top of a CdSe nanocrystal superlattice

and the right one shows the side of a cleaved Fe2O3 nanocrystal superlattice.

The trace represents small angle x-ray scattering (SAXS) of the Fe2O3 nanocrystal superlattice.

For more, see

“Formation of Thick, Large-Area Nanoparticle Superlattices in Lithographically Defined Geometries,” A. Akey, C. Lu, L. Yang, and I. P. Herman,

Nano Lett. 10, 1517 (2010).

Back to top

|

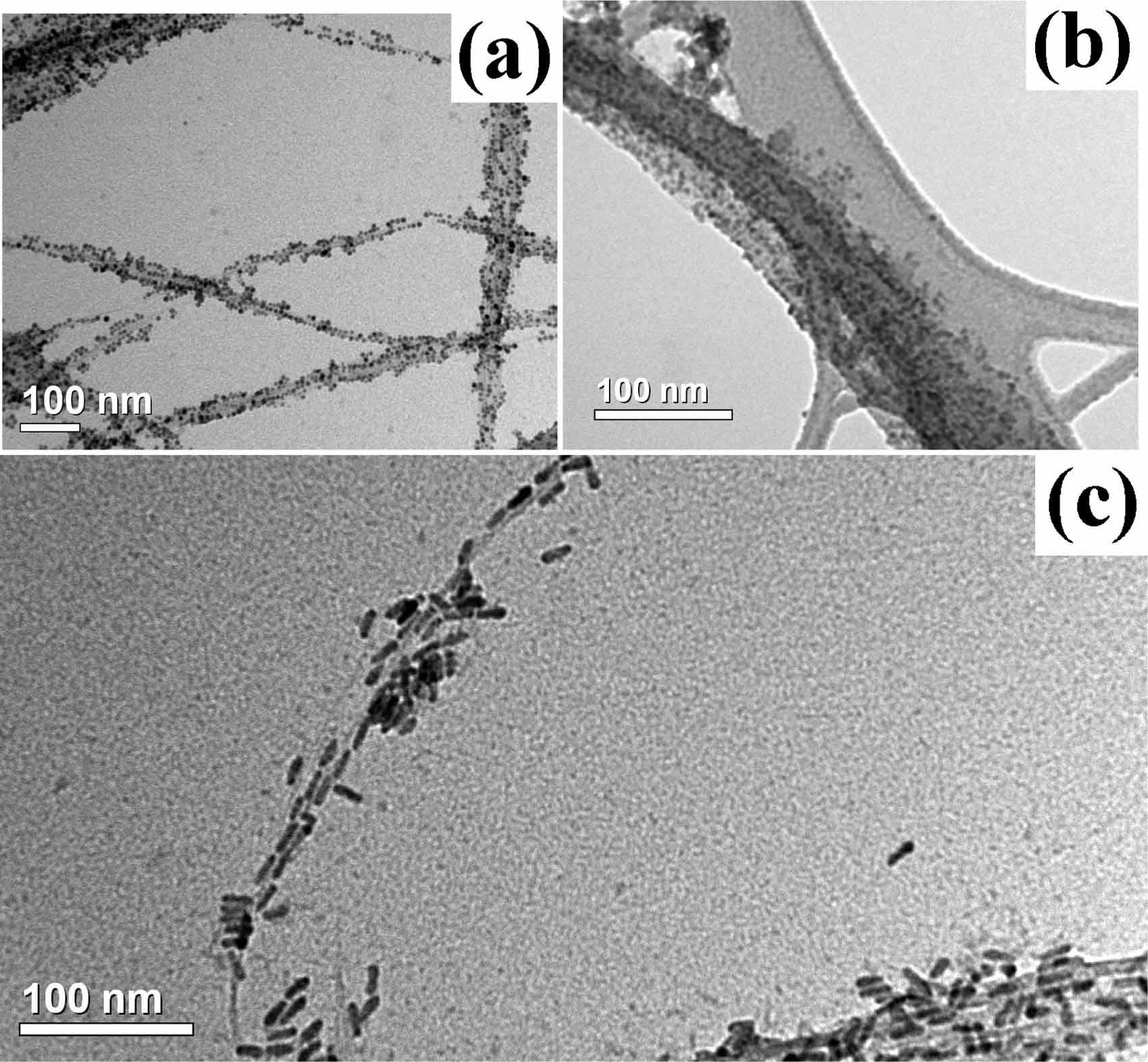

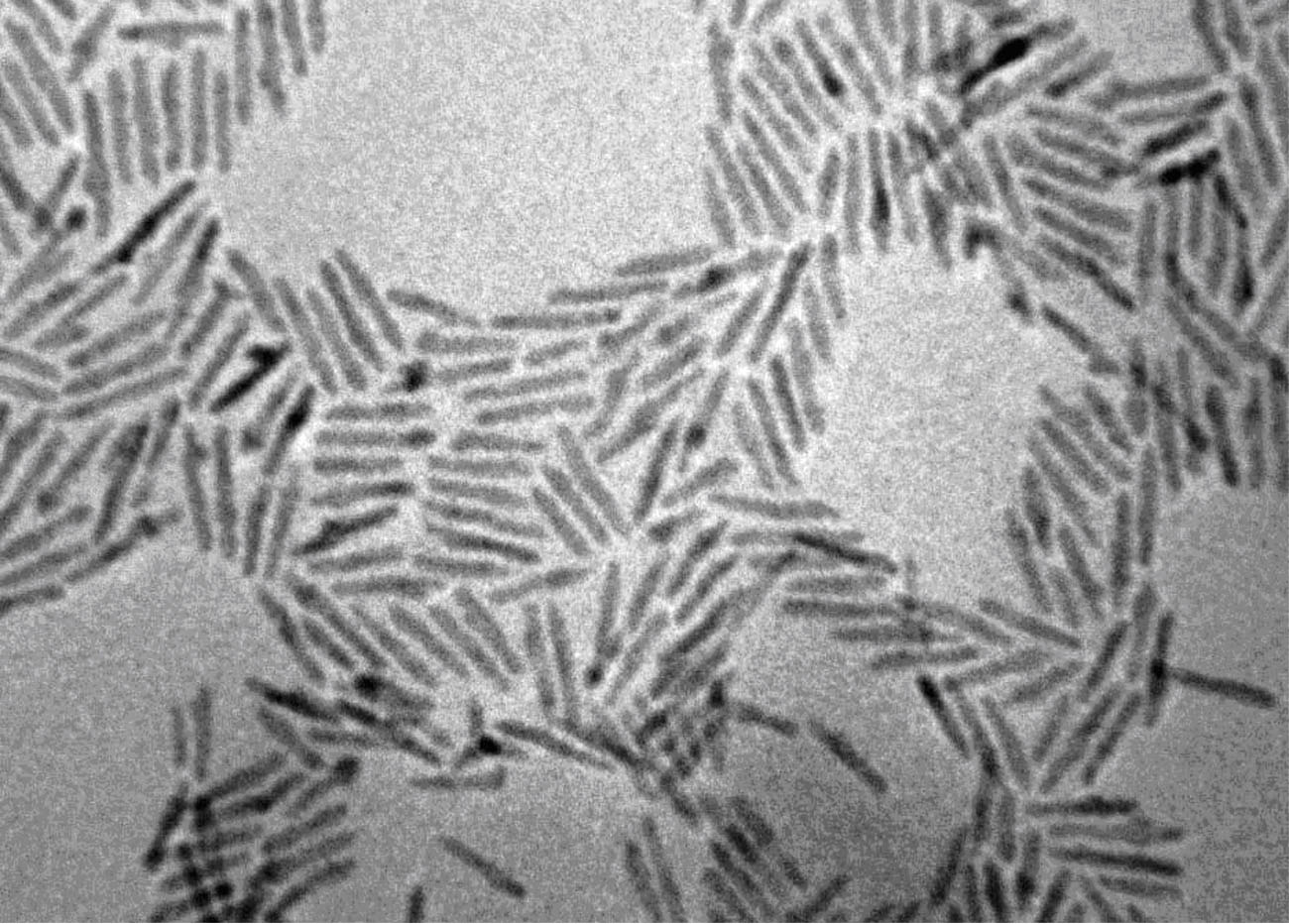

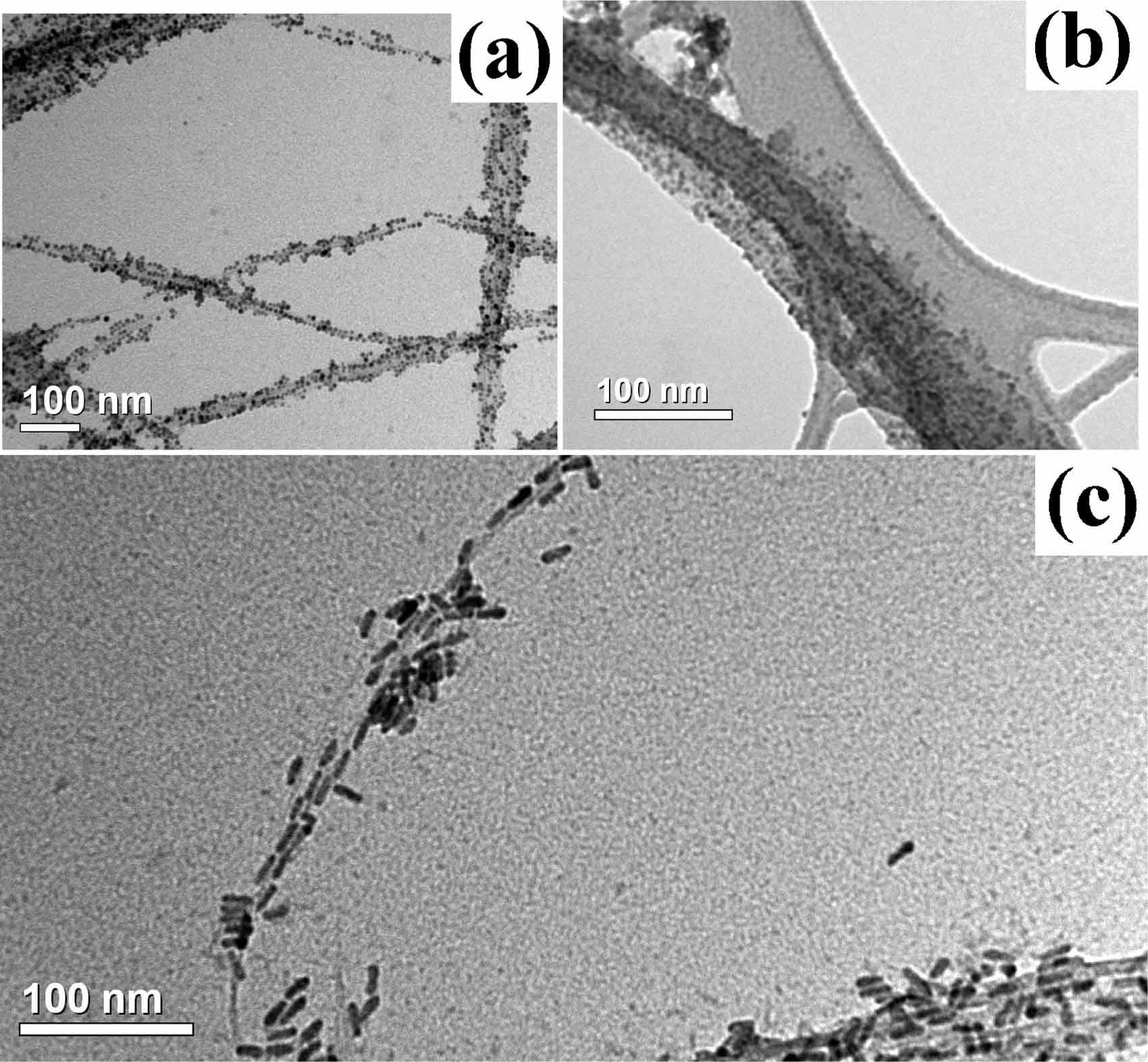

Formation of Nanocrystal-Carbon Nanotube Hybrid Materials

The Herman group is using methods to form hybrids of nanocrystals and carbon nanotubes that may have novel optical

and electrical properties. Both components have signature optical properties and coupling between them may be very interesting.

The left SEM shows HIPCo carbon nanotubes with (a) CdSe nanparticles, (b) core shell particles and (c) CdSe nanorods,

and the right SEM shows a hybrid of a CNT and CdSe nanoparticles on a surface, with an AFM inset.

For more, see

“Versatile Formation of

CdSe Nanoparticle-Single Walled Carbon Nanotube Hybrid Structures,” C. Lu, A. Akey, W. Wang, and I. P. Herman,

J. Am. Chem. Soc. (Commun.) 131, 3446 (2009).

Back to top

|

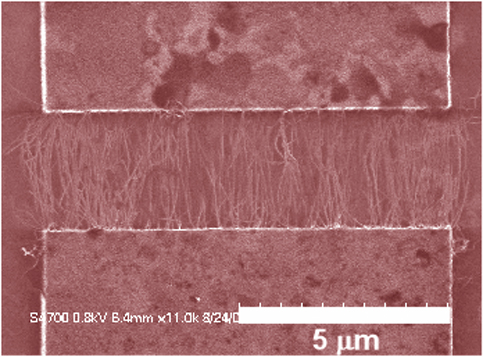

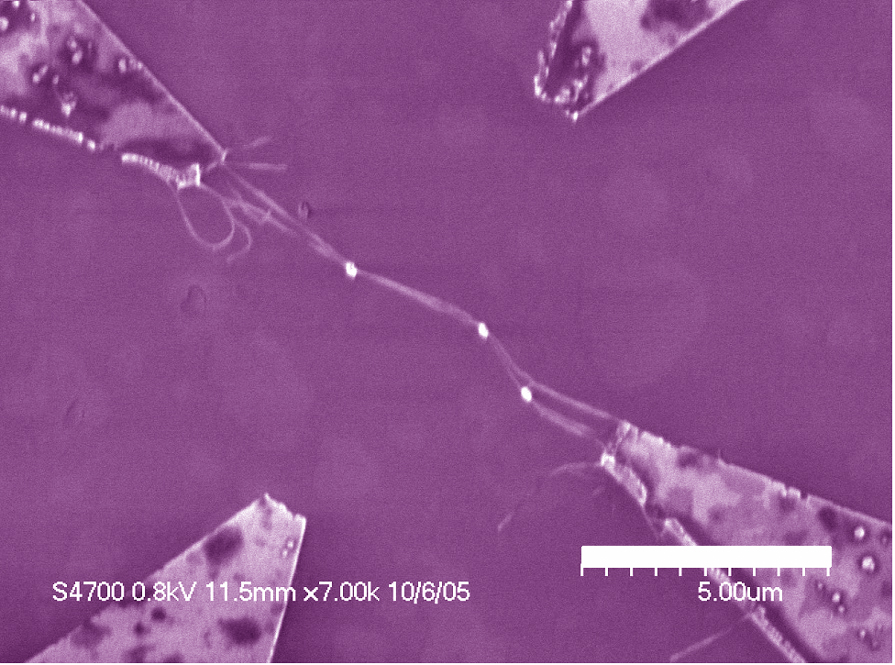

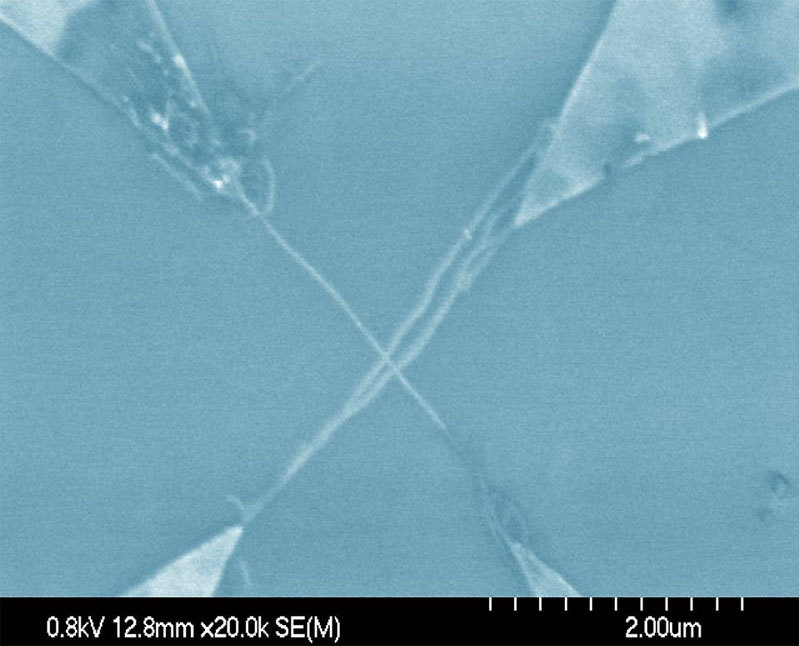

Spatially Controlled AC Dielectrophoretic Placement of Carbon Nanotubes in Device Structures

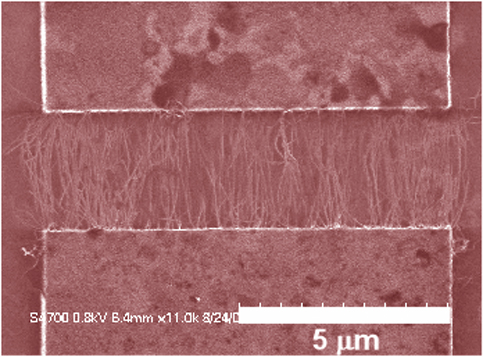

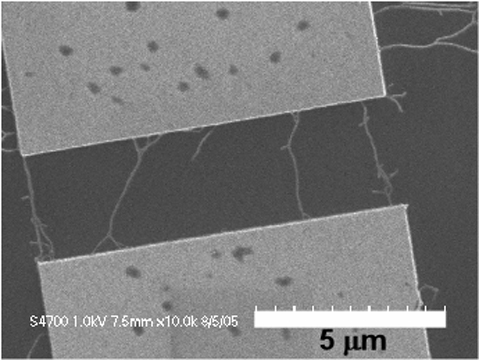

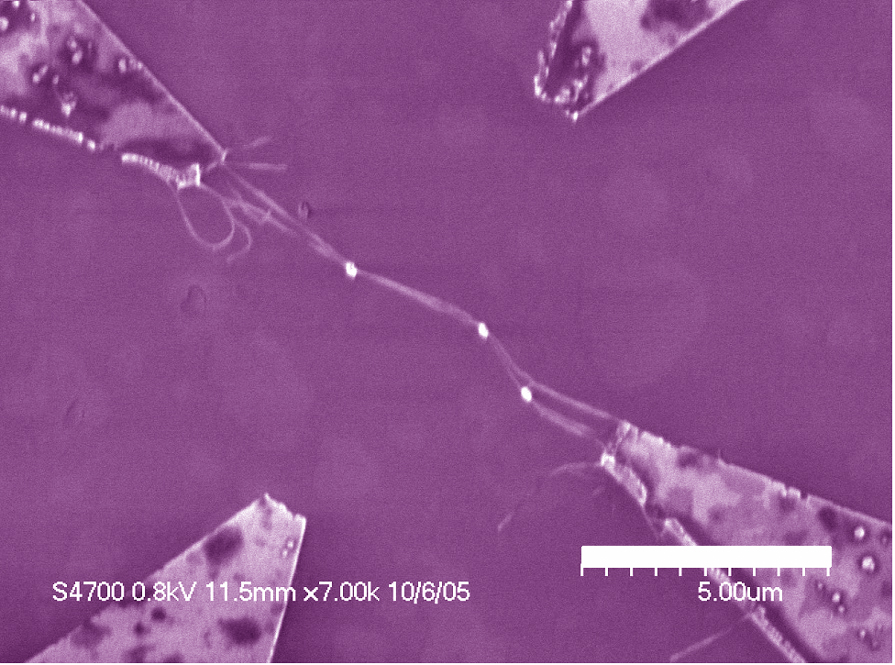

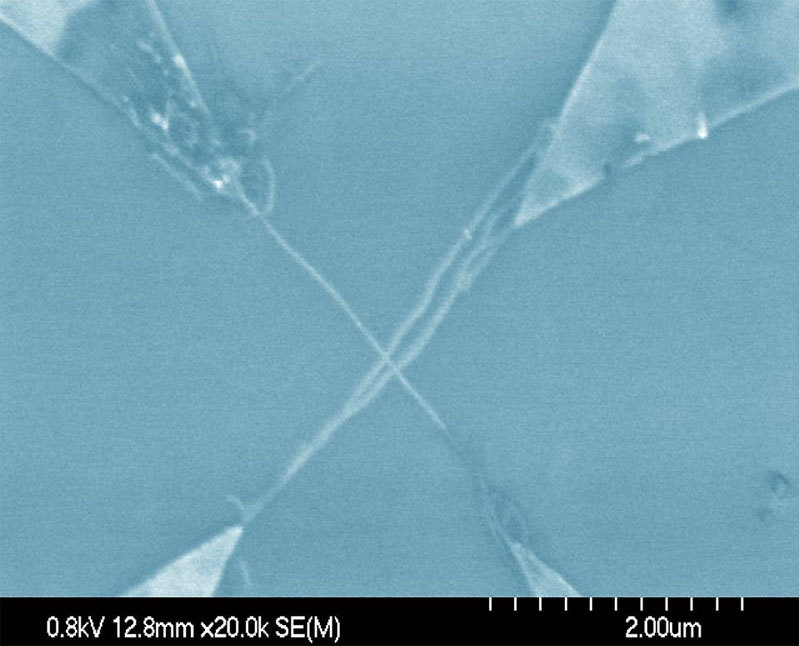

The Herman group is developing and using methods to controllably place single walled carbon nanotubes (CNTs) in multi-electrode device geometries by using dielectrophoretic deposition (DEPD) and other methods. The top row shows SEMs of DEPD without (left) and with (right) control by series resistors. The bottom row shows control using floating posts (left) and controlled deposition of crossed CNTs (right).

For more, see

"Precise Positioning of Carbon Nantoubes by AC Dielectrophoresis Using Floating Posts" S. Banerjee, B. White, L. Huang, B. J. Rego, S. O’Brien, and I. P. Herman, Appl. Phys. A 86, 415-419 (2007) and “Precise Positioning of Single-Walled Carbon Nantoubes by AC Dielectrophoresis,” S. Banerjee, B. White, L. Huang, B. J. Rego, S. O’Brien, and I. P. Herman, J. Vac. Sci. Technol. 24, 3173 (2006).

Back to top

|

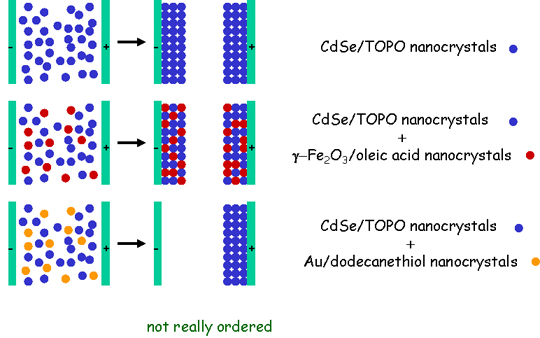

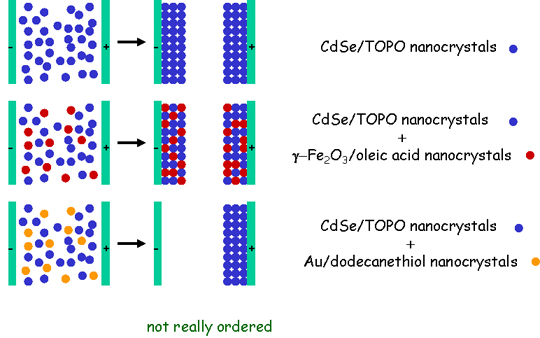

Electrophoretic Deposition of Films of Mixtures of CdSe and Fe2O3 Nanocrystals

In some cases,

electrophoretic deposition using mixtures of nanocrystals produces

films composed of mixtures of the nanocrystals. This is shown below

schematically for mixtures of CdSe and Fe2O3

nanocrystals. Such film mixtures are potentially multifunctional

nanomaterials. When Au nanocrystals are added to a hexane solvent

containing either CdSe or Fe2O3 nanocrystals, there is deposition of a film containing either only CdSe or Fe2O3 nanocrystals, respectively, and this occurs on only one electrode. This is a collaboration with the O'Brien and Levicky groups.

For more, see "Addition, Suppression, and Inhibition in the Electrophoretic

Deposition of Nanocrystal Mixture Films for CdSe Nanocrystals with γ-Fe2O3 and Au Nanocrystals,"

M. A. Islam, Y. Xia, M. L. Steigerwald, M. Yin, Z. Liu, S. O'Brien, R. Levicky, and I. P. Herman,

Nano Letters 3, 1603-1606 (2003).

Back to top

|

|

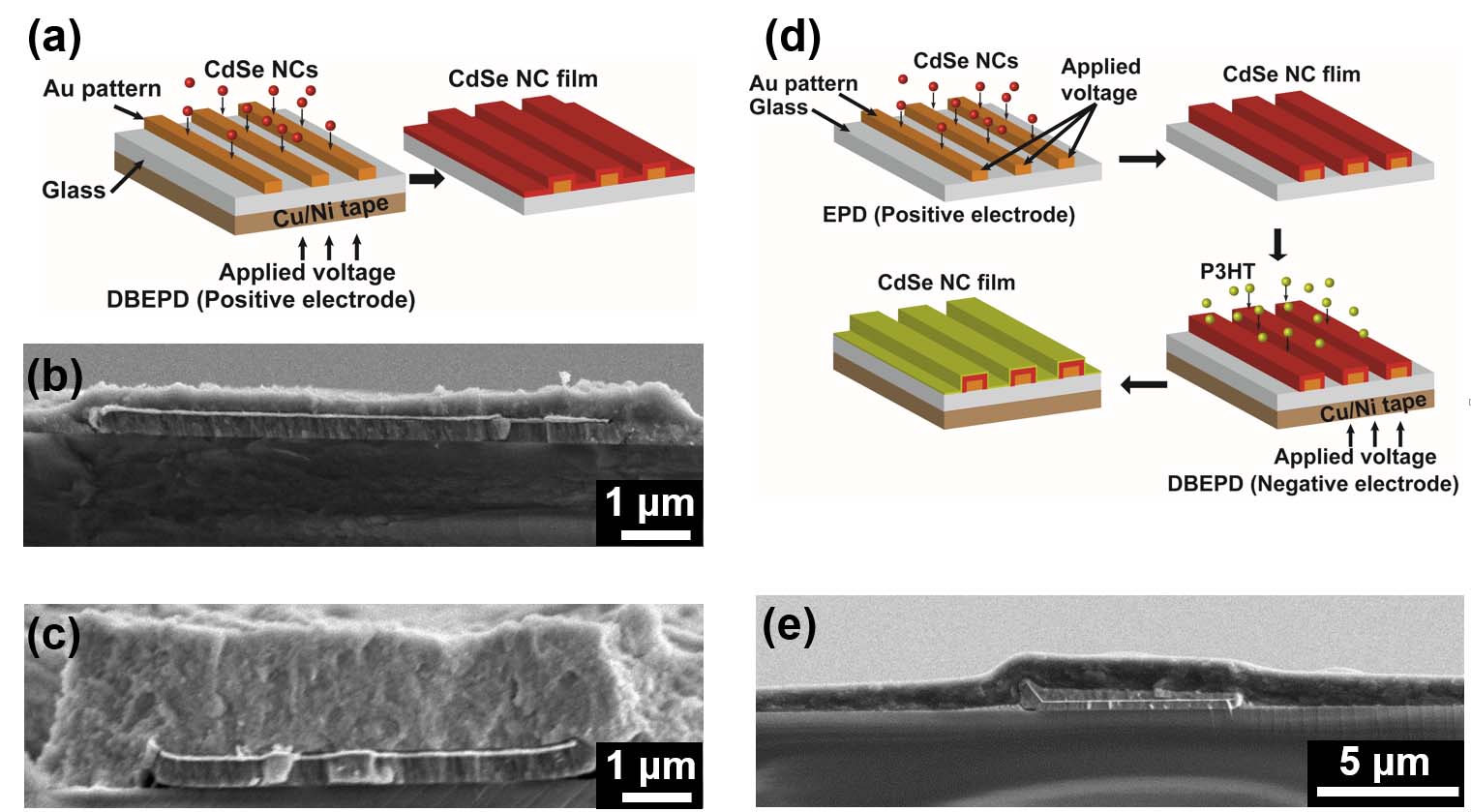

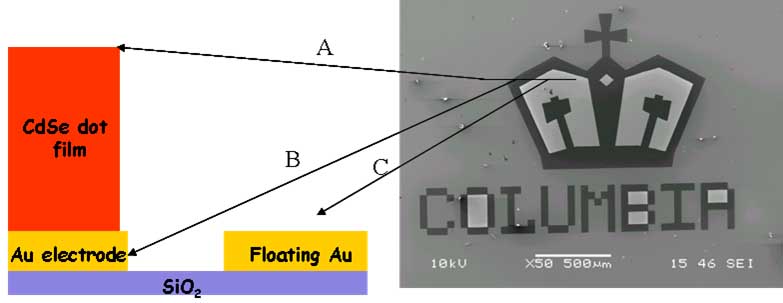

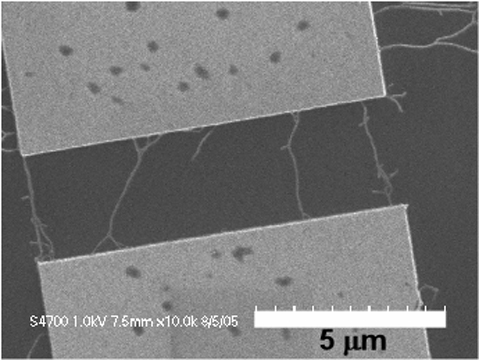

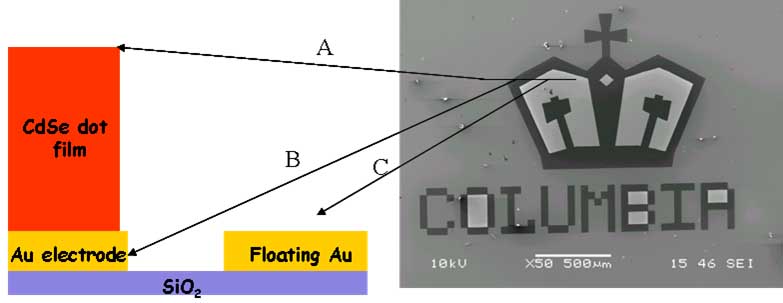

The Herman group is

examining the use of electrophoretic deposition methods to form thick,

smooth, robust films of CdSe nanocrystals. The figure on the top shows

particles selectively depostied on metal regions in contact with the

electrode (gray), with no deposition on oxide (dark) or metal regions

isolated from the electrode (bright). Depositon about of a particle

film (gray) around an oxide spacer (dark) is shown on the bottom. For

very thick films, strain leads to film fracture, as is seen in the SEM

(lower, right). Such cracking is not uncommon when there is some

solvent evaporation during film drying.

For more, see

"Electric-Field Assisted Deposition of Patterned Nanocrystal Films using Thermally Charged CdSe Nanocrystals,"

M. Islam and I. P. Herman, Appl. Phys. Lett. 80, 3823-3825 (2002) and "Controlled Electrophoretic Deposition of Smooth and Robust Films of CdSe Nanocrystals,"

M. A. Islam, Y. Xia, D. A. Telesca, Jr., M. L. Steigerwald, and I. P. Herman,

Chem. Mater 16, 49-54 (2004).

Back to top

|

Real-time Monitoring of Organic Surface Ligands and Solvent During the Self-Assembly of Nanocrystal Arrays

The densities of

surface ligands and solvent molecules are being followed during the

self-assembly of CdSe nanocrystals into arrays by using

multiple-reflection attenuated total internal reflection (ATIR)

spectroscopy. This is performed in a Fourier transform infrared (FTIR)

spectrometer in which the arrays formed on a ZnSe prism. During the

self-assembly of CdSe nanocrystals passivated by pyridine that are

dissolved in pyridine, the 1436.1 cm-1 peak of neat pyridine is followed along with that at 1445.2 cm-1 due to pyridine bound to the CdSe surface (below).

The

solvent evaporates in about 30 minutes during the self-assembly of

~200-monolayer thick arrays in an argon ambient (inset below). The

pyridine bound to the surface slowly leaves the surface (inset, open

symbols), but about 35% remains after drying for several days (main

figure, below). Since pyridine only weakly binds to the surface, it had

been commonly thought that no pyridine would remain after extensive

drying. While this is not true, there are still significant changes to

the surface during drying. This result is important for the MRSEC

studies of the self-assembly of arrays and the properties of these

arrays. This monitoring method is also being used to follow the surface

of exchange of TOPO and pyridine ligands, and related processes.

For more, see

"Organic Ligand and Solvent Kinetics during the Self Assembly

of CdSe Nanocrystal Arrays using Infrared Attenuated Total Reflection,"

B. Kim, L. Avila, L. Brus, and I. P. Herman, Appl. Phys. Lett. 76,

3715-3717 (2000).

Back to top

|