Fiber Optic Pressure Sensors

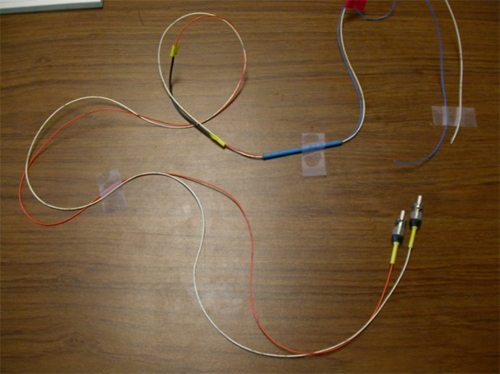

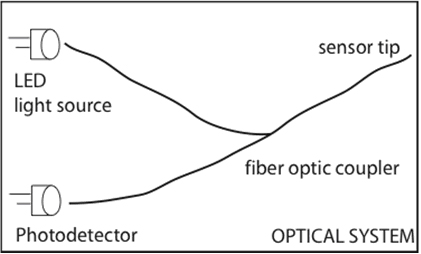

Our fiber optic pressure sensors consists of 3 basic parts:

1. A couplerOur coupler consists of two optic fibers that have been melted together – we buy it this way from Fiber Instrument Sales, or Gould. It has two ST type connectors on one side and two loose ends on the other side. A light emitting diode (LED) is connected to one of the ST connectors and a photodetector is connected to the other.2. An etched optic fiber

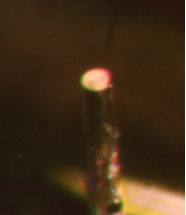

This fiber has been etched on one end with hydrofluoric acid until it has a diameter of approximately 60 µm. The non-etched end of the fiber is fused to one of the loose ends of the coupler. The etched end of the fiber is then threaded into the sensor tip until it is approximately 50 µm away from the pressure sensitive membrane.3. A sensor tip

Our sensor tips consist of a hollow core glass fiber with an inner diameter of 75 µm. The sensor tip has a pressure sensitive membrane one side. This membrane is formed by floating a drop of photosensitive polymer adhesive on water, curing it with a UV lamp and scooping it up by the sensor tip. It is then coated with a thin layer of gold.

The light that travels to the membrane from the LED will reflect off of the gold membrane and return to the fiber to be detected by the photodetector. When the membrane moves as a result of sound pressure, it changes the amount of light that travels back to the photodetector, which is how it functions as a pressure sensor.