EXPERIMENT 4

Separation of Liquid Mixtures by Distillation

BACKGROUND

Distillation is one of the most useful methods for the separation and purification of liquids. It is perhaps the oldest separation technique known. It is most commonly used to purify a liquid from either liquid or solid contaminants by exploiting differences in their boiling points.

Types of Distillation

Simple distillation can separate compounds cleanly if the difference in boiling points between the compounds is greater than 70 °C. The process is useful to further purify relatively pure liquids, to get rid of volatile organic solvents, or to separate the liquid from polymerization products and mineral impurities.

Fractional distillation is a separation technique that is used when the boiling point differences of the compounds in a mixture to be separated are not large enough to employ the simple distillation technique. The components to be separated are collected in different fractions, whose identity are usually then confirmed via spectroscopy or TLC (thin layer chromatography). The first fraction, (or the first mixture between fractions) usually just a few drops, is called the forerun. It contains any highly volatile substances that were present in the sample, and is a kind of first rinse of the distillation glassware. It may be combined with the next fraction if analysis warrants.

Vacuum distillation is used to purify compounds that can decompose before reaching their boiling point at atmospheric pressure. By lowering the gas pressure above a liquid, that liquid can be encouraged to boil at a lower temperature. This is important if it would break down at a higher one.

Steam distillation is also used for high boiling point substances that decompose before the boiling point is reached. In this case, instead of using a vacuum, the liquid in question is mixed with another, immiscible liquid. The presence of the second liquid causes both to boil at a temperature lower than the regular boiling points of either liquid. For example, naphthalene, a solid at room temperature that boils at 218°C, can be melted and mixed with water. Because the two are immiscible, they will steam distill at a temperature around 90°C, less than 100°C (the boiling point of water) and well below 218 °C. In all steam distillations, the distillate collected will be a mixture of both liquids, but since they are immiscible, they can generally be separated easily via extraction.

PROCEDURE

Fractional Distillation Using Microlab

In this experiment you will determine the composition of a mixture of ethanol and water. You will separate the components of the mixture by fractional distillation. You will use the MicroLab data acquisition software to monitor the progress of the distillation. A thermistor (an electronic temperature sensor) will be used to observe the boiling points of the components of the mixture, and the volume of each will be determined by collecting the fractions in a graduated cylinder.

PART 1. Calibration of Thermistor.

At the beginning of the experiment, the thermistor must be calibrated to ensure accurate temperature readings. You will calibrate the thermistor using samples of water at well-defined temperatures.

- 1. For the calibration, you will need about 50 mL of boiling water. Heat this water in a beaker on a hot plate. Remember to add a boiling stick!

- 2. Connect the MicroLab thermistor to a port on the MicroLab interface and open a new experiment.

- 3. Click “Add Sensor,” select “Temperature (thermistor)” from the pull-down menu, and select the port where you inserted it. Click “Next” to bring you the thermistor calibration window.

- 4. Click “Perform New Calibration.” This will open another window entitled “Calibrate a Sensor.”

- 5. Click “Add Calibration Point.” Insert the thermistor and a thermocouple into the beaker of boiling water. You should notice the measured value of the thermistor increasing. Once the rate of change of the measured value becomes constant, read the temperature on the thermocouple (to the nearest 0.1°C) and type that in as the actual value. Then click “OK.”

- 6. Prepare an ice bath (with crushed ice and some water) in a recrystallizing dish. Insert the thermistor and the thermocouple and calibrate this point as you did for the boiling water. Do the same for a sample of lukewarm tap water.

- 7. In the “Calibrate a sensor” window, you should see a graph of the three calibration points you made. To obtain a best-fit curve, select “First Order (Linear)” from the choices on the left. Click “Accept and Save this Calibration.” A small window will open asking for units; enter “(C).” Save the calibration as “Thermistor Calibration.” (If this file already exists, replace it.) Click “Save” and then click “Finish.”

The thermistor is now calibrated to track the temperature of the vapor during the distillation.

PART 2. Distillation Setup.

- 1. Place about half of your sample (roughly 10 mL) in a 50 mL round bottom flask. Since you will be boiling this solution, add a magnetic stir bar. Why is it important to use a stir bar in a distillation?

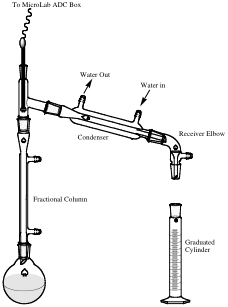

- 2. Set up a distillation apparatus according to the diagram below. Clamp the 50 mL round-bottom flask (the pot) at least a foot above the floor of the hood and construct a fractionating column by packing a condenser with steel wire or glass wool. You should lightly grease all joints in your setup unless they are still greasy from previous usage.

Fractional Distillation setup

- 3. Insert the thermistor into a rubber thermometer adapter fitted onto a glass straight tube adapter by placing a drop of glycerol onto the bulb of the thermometer and gently pushing the thermometer through the thermometer adapter. Your TA will demonstrate the proper way to insert a thermometer. To avoid injury make sure that as you push you gently rotate the bulb of the thermometer. Proceed slowly.

- 4. Adjust the thermistor so that the bulb is completely below the sidearm (leading to the condenser) in the three-way adapter. This will result in an accurate temperature reading because the thermistor will be totally immersed in boiled vapor. Seal up the hole using teflon wrap to prevent vapors from escaping during the distillation.

- 5. Seal the condenser to the open joint of the three-way adapter and clamp it. Use a blue plastic clip to help hold it in place. Attach a vacuum adapter to the end of this condenser and clip it as before.

- 6. Place a 100 mL graduated cylinder at the bottom of the vacuum adapter. This last flask, the collection flask, should be surrounded with an ice bath to ensure that any liquid you collect does not evaporate out.

- 7. Place a stirring-hot plate on a jack under your pot. This plate will be used only to stir and not to heat.

- 8. Obtain a heating mantle and plug it into a variac. Plug the variac into the wall and switch it on. The variac is a device that modulates AC current. Wall current is 120 V; a variac can adjust that to anywhere between 0 and 120 V. Plugging the heating mantle into a variac allows you to control the temperature by controlling the voltage supplied to it. Test the mantle and variac by briefly turning the dial up to 100%. The mantle should get warm within ten seconds or so. Turn the variac down to 0 once you have confirmed that it and the mantle work. The variac should be left at 0 until you are ready to heat. Place the heating mantle on the hot plate under your pot.

- 9. The hot plate and mantle should be lifted up on a jack. Raising your heat source allows you to quickly remove it in case of violent boiling or fire. If you need to cool your pot quickly, you can simply lower the jack. Without the jack, you would have to slide the hot mantle or hot plate out or lift the hot pot and risk a burn.

- 10. The last step towards completing the distillation apparatus is running water through the condenser. What would be the best way?

- 11. Ask your TA to inspect your setup before beginning to heat. When ready, start stirring and turn on the variac. It should be set low at first, to 20-30%, to avoid boiling too quickly. If, after a few minutes, the solution does not boil, you may increase the variac to 50% or so. Ask your TA before turning it any higher. If increasing the variac setting doesn’t work, you may want to insulate your pot with some cotton wrapped in aluminum foil. Avoid heating too quickly--boiling too fast can cause the vapor to travel past the thermometer too quickly, resulting in an artificially low measured boiling point. Furthermore, too much heat could cause your compound to decompose.

You should eventually see your liquid boil. Monitor the temperature on the MicroLab software. Typically the measured temperature will stay at or near room temperature until the boiled liquid (now a gas) rises up to the thermistor, at which point the temperature will jump up rapidly to the boiling point of that liquid. As your liquid boils, the temperature should stay more or less constant as newly formed gas continues to warm the thermistor. As you distill, you should also see drops of liquid roll down the inside of your condenser and fall into your collection flask. Continue distilling until the pot is nearly dry (less than 25% of its original volume). Again, you should never distill to dryness. Lower the hot plate and heating mantle and switch off the variac. Remove your collection flask (now full of your compound) from the ice.